Iron Chromium Aluminum Wire 1Cr13Al4 for Industrial Furnace

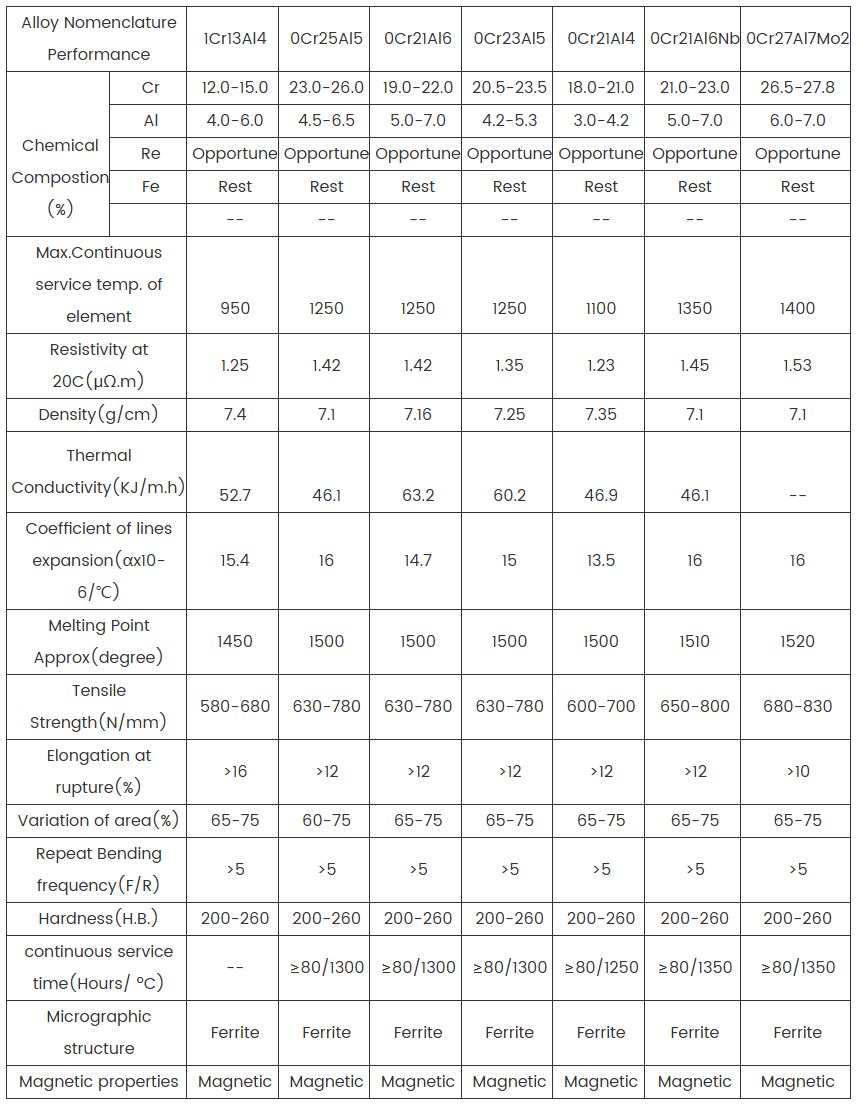

Engineered from premium Iron Chromium Aluminum alloy, the 1Cr13Al4 wire delivers exceptional high-temperature resistance, oxidation protection, and electrical efficiency for industrial furnaces, kilns, and ovens. This cost-effective FeCrAl heating wire outperforms traditional options in medium-temperature applications, ensuring long service life and reliable performance in global industrial settings.

- Overview

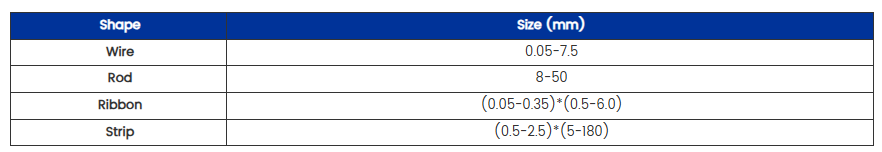

- Specification

- Applications

- FAQs

- Recommended Products

- Exceptional Oxidation Resistance in Chromium Aluminum Iron Wires for Extended Durability: Forms a dense Al₂O₃ layer at high temperatures, preventing degradation in oxidative atmospheres common to furnace environments.

- High Electrical Resistivity and Low Temperature Coefficient in FeCrAl Heating Elements: Ensures stable performance and uniform heating with minimal energy loss, ideal for precise temperature control in kilns and ovens.

- Superior High-Temperature Strength in Industrial Resistance Heating Wires: Maintains mechanical integrity and creep resistance up to 950°C, supporting heavy-duty use in heat treatment and drying systems.

- Cost-Effective and Lightweight Properties of Iron Chromium Aluminum Alloys: Lower density than NiCr alternatives reduces material costs and installation weight while delivering comparable or better oxidation resistance for global industrial applications.

- Versatile Formability in FeCrAl Resistance Wires for Custom Heating Coils: Available in round, flat, or coiled formats, easily integrated into electric furnaces, locomotive brake resistors, and household appliances.

✓ Product Description

The 1Cr13Al4 FeCrAl alloy wire is a ferritic iron-chromium-aluminum material optimized for electrical resistance heating in demanding environments. With high resistivity, low temperature coefficient, and strong mechanical properties, it excels in industrial furnace heating elements, offering superior oxidation resistance through a protective aluminum oxide layer. This makes it ideal for medium-temperature operations up to 950°C, providing a lightweight, economical alternative to nickel-chromium (NiCr) wires for furnaces, ovens, drying equipment, and more. Its balanced composition—13% chromium and 4% aluminum—enhances corrosion resistance and thermal stability, supporting efficient heat generation in metallurgy, automotive, and military sectors worldwide.

✓ Product Features

Key Features of 1Cr13Al4 FeCrAl Alloy Wire for Efficient Resistance Heating in Industrial Furnaces

✓ Product Applications

Diverse Applications of 1Cr13Al4 Iron Chromium Aluminum Wire in Industrial Heating Systems and Furnaces

- Medium-Temperature Industrial Furnaces and Heat Treatment Ovens: Perfect for heating elements in processes requiring reliable oxidation resistance and high resistivity up to 950°C.

- Drying Equipment, Kilns, and Ovens Using FeCrAl Resistance Heating Wires: Provides efficient, uniform heat for ceramics, metallurgy, and food processing industries.

- Automotive, Locomotive, and High-Speed Vehicle Brake Resistors: Used in electric systems for its mechanical strength and thermal stability under cyclic heating.

- Military, Aerospace, and Metallurgy Heating Elements: Supports high-reliability applications demanding corrosion-resistant FeCrAl alloys in extreme conditions.

- Household Appliances and General Industrial Drying Systems: Cost-effective solution for medium-temp heating in global manufacturing and R&D facilities.

✓ Product FAQ -1Cr13Al4 FeCrAl Resistance Wires for Industrial Furnace Heating

1.What is the maximum operating temperature for 1Cr13Al4 Iron Chromium Aluminum Wire in furnaces?

The 1Cr13Al4 FeCrAl alloy supports continuous operation up to 950°C in oxidizing atmospheres, making it suitable for medium-temperature industrial heating without rapid degradation.

2.How does the oxidation resistance of Chromium Aluminum Iron alloys enhance FeCrAl heating element longevity?

The aluminum content promotes a self-healing Al₂O₃ oxide scale that protects against high-temperature corrosion, extending service life in furnaces, kilns, and ovens compared to NiCr wires.

3.Is 1Cr13Al4 wire recommended for kiln, oven, and drying equipment applications?

Yes, its high resistivity, low density, and excellent thermal strength make it ideal for these medium-temperature industrial systems, offering efficient heating and cost savings.

4.What are the key advantages of FeCrAl resistance wires over NiCr for industrial furnace use?

FeCrAl alloys like 1Cr13Al4 provide better oxidation resistance, lower weight, and higher maximum temperatures in many cases, at a more competitive price for global projects.

5.Where can I source high-quality 1Cr13Al4 Iron Chromium Aluminum Wire for worldwide industrial applications?

Reliable suppliers offer bright annealed, coiled, or spooled formats compliant with international standards, with customization for furnace heating elements and fast global shipping.