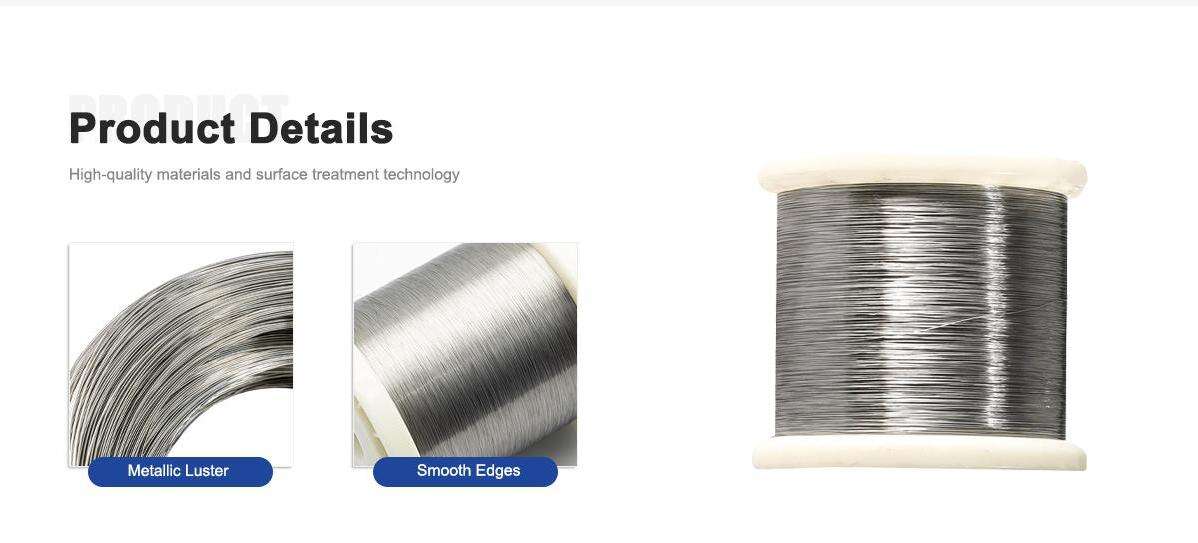

High Temperature Nichrome Heating Wire with Stable Resistivity

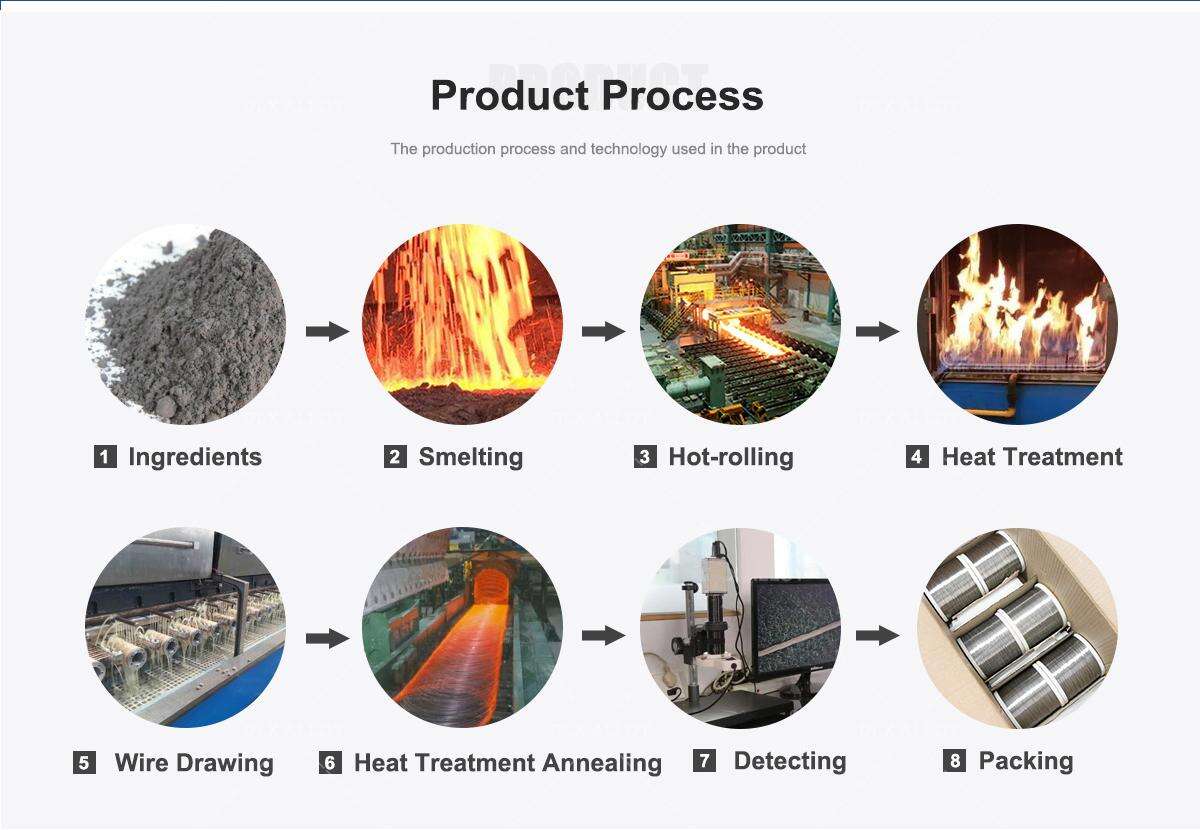

Our high temperature Nichrome heating wire with stable resistivity is engineered from premium nickel-chromium alloys, providing exceptional thermal stability and electrical resistance for demanding industrial and laboratory uses. Ideal for applications requiring reliable heat generation, this resistance wire ensures consistent performance, oxidation resistance, and longevity in high-heat settings like furnaces, kilns, and heating elements. Perfect for manufacturers seeking robust electric heating solutions with minimal maintenance.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Superior Heat Resistance and Oxidation Protection: Withstands temperatures up to 1200°C, featuring a protective oxide layer for extended life in high-temperature heating wire applications.

- Stable Electrical Resistivity: Maintains consistent ohm values across temperature fluctuations, ideal for precision resistance wire in electric furnaces and kilns.

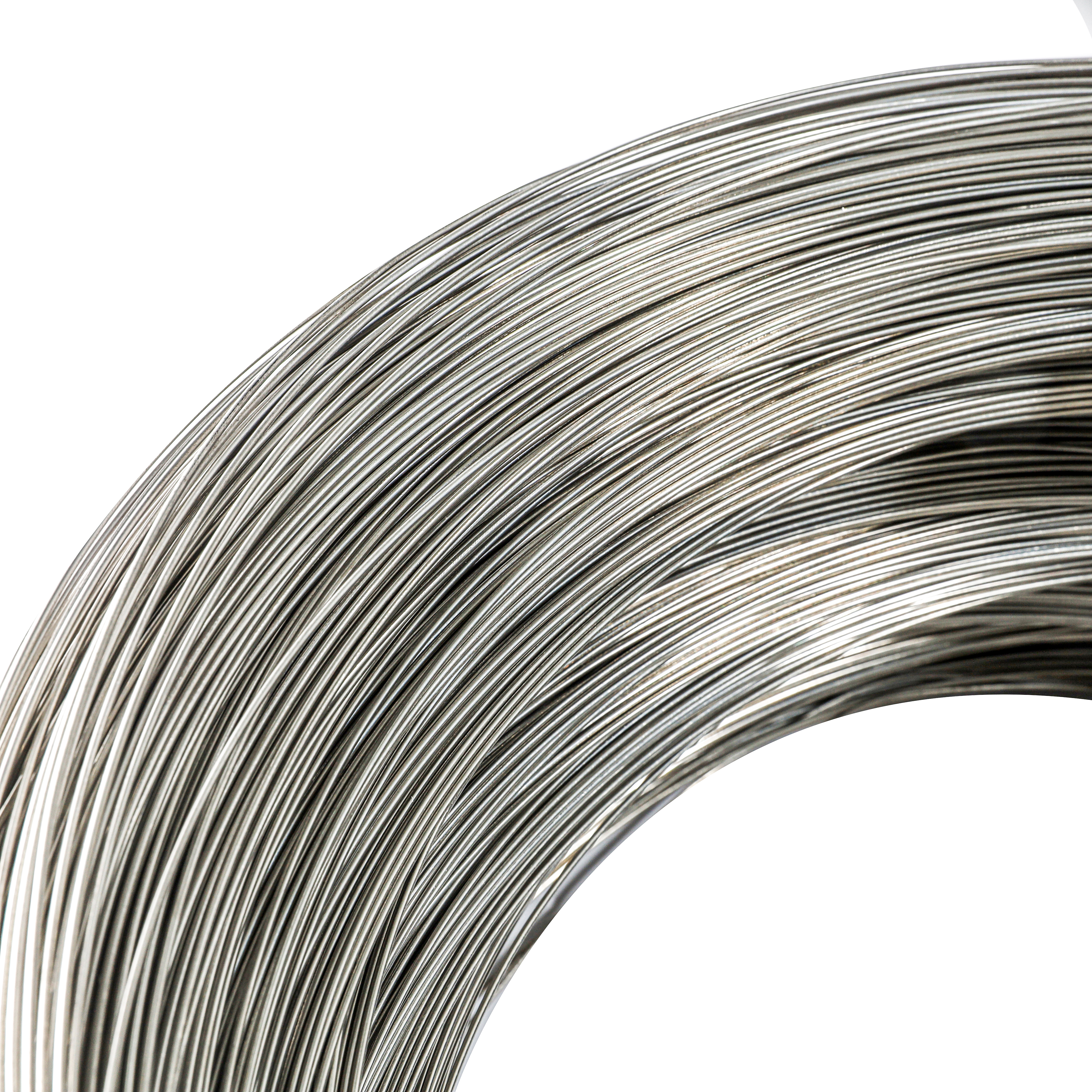

- High Tensile Strength and Durability: Nickel-chromium alloy construction ensures flexibility and strength, reducing breakage in industrial heating element setups.

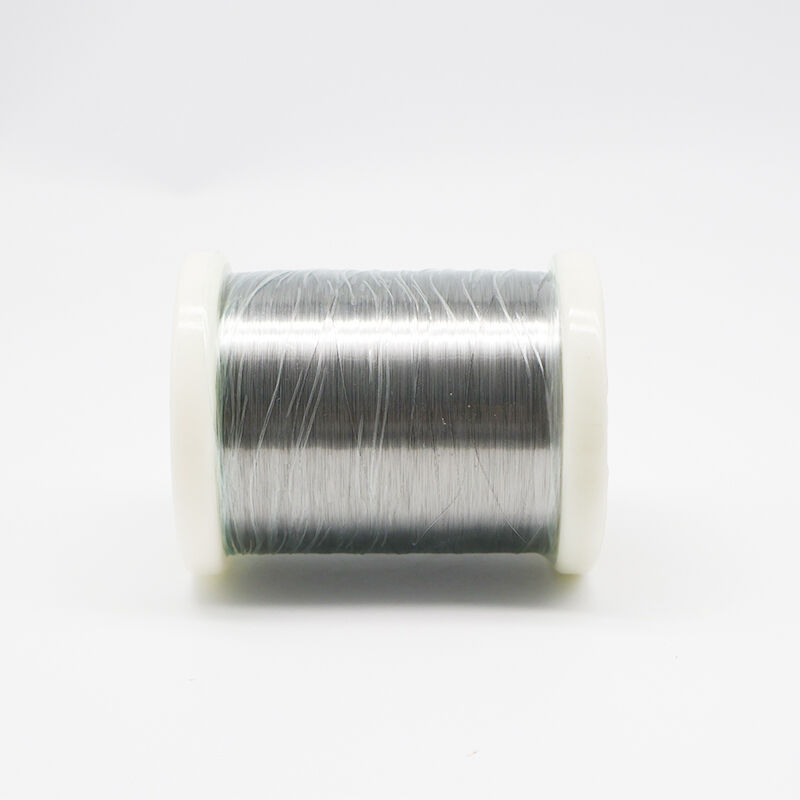

- Customizable Specifications: Available in various gauges, lengths, and coil forms to match specific resistivity requirements for global markets like the US, EU, and Asia-Pacific.

- Corrosion-Resistant Design: Performs reliably in humid or chemical-exposed environments, enhancing longevity for laboratory heating wire and appliance components.

- Energy-Efficient Performance: Low thermal conductivity promotes efficient heat generation, making it a cost-effective choice for sustainable electric resistance heating solutions.

High Temperature Nichrome Wire Overview:

This overview highlights our Nichrome heating wire, a versatile nickel-chromium alloy known for its high melting point and stable resistivity. Commonly used in resistance heating applications, this wire excels in environments up to 1200°C, making it a staple in electric heating systems worldwide. From North American manufacturing hubs to European labs and Asian production lines, our Nichrome wire supports efficient energy transfer, corrosion resistance, and customizable diameters for various resistivity needs. Whether for DIY heating projects or large-scale industrial furnaces, it delivers reliable performance with low thermal expansion.

Nichrome Alloy Heating Wire Features:

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Nichrome Resistance Wire Applications:

- Electric Furnace and Kiln Heating Wire: Essential for high-temperature processes in ceramic kilns, metal annealing furnaces, and laboratory ovens, providing uniform heat distribution.

- Household Appliance Repair and Heating Elements: Used in toasters, hair dryers, space heaters, and electric stoves for dependable nichrome coil wire performance.

- Industrial Heating Systems with Nichrome Alloy Wire: Ideal for resistance heating in manufacturing equipment, such as plastic molding machines and heat sealing devices across US and European factories.

- Laboratory and Scientific Equipment Resistance Wire: Supports precise temperature control in incubators, sterilizers, and analytical instruments in research facilities globally.

- Custom Heating Coil Applications in Appliance Wire: Perfect for DIY projects or OEM integrations in radiant heaters and vaping devices requiring durable high-temperature wire.

- Commercial Oven and Food Processing Heating Elements: Ensures consistent baking and drying in professional kitchens and food industry setups in Asia-Pacific regions.

Nichrome Heating Wire FAQs:

1.What is Nichrome wire and why is it used in high-temperature heating applications?

Nichrome wire is a nickel-chromium alloy resistance wire prized for its high melting point and stable resistivity, making it ideal for electric heating elements in furnaces, kilns, and appliances where consistent performance is crucial.

2.How does the stable resistivity of this heating wire benefit industrial users?

The stable resistivity ensures minimal variation in electrical resistance over temperature changes, leading to efficient energy use and longer lifespan in high-temp environments like manufacturing plants in the US or Asia.

3.Can this Nichrome alloy wire be customized for specific resistance heating needs?

Yes, we offer customization in diameter, length, and alloy composition to match your resistivity requirements, suitable for global standards in electric furnaces and lab setups.

4.What temperatures can this resistance heating wire withstand?

Our high-temperature Nichrome wire operates effectively up to 1200°C, with excellent oxidation resistance for prolonged use in demanding industrial and laboratory heating systems.

5.Is this electric heating wire suitable for international shipping and use?

Absolutely, compliant with global regulations, it's shipped worldwide to regions like Europe, North America, and the Asia-Pacific for versatile resistance wire applications.