High-Resistivity Wire NiCr 80/20 - Oxidation-Proof for Chemical

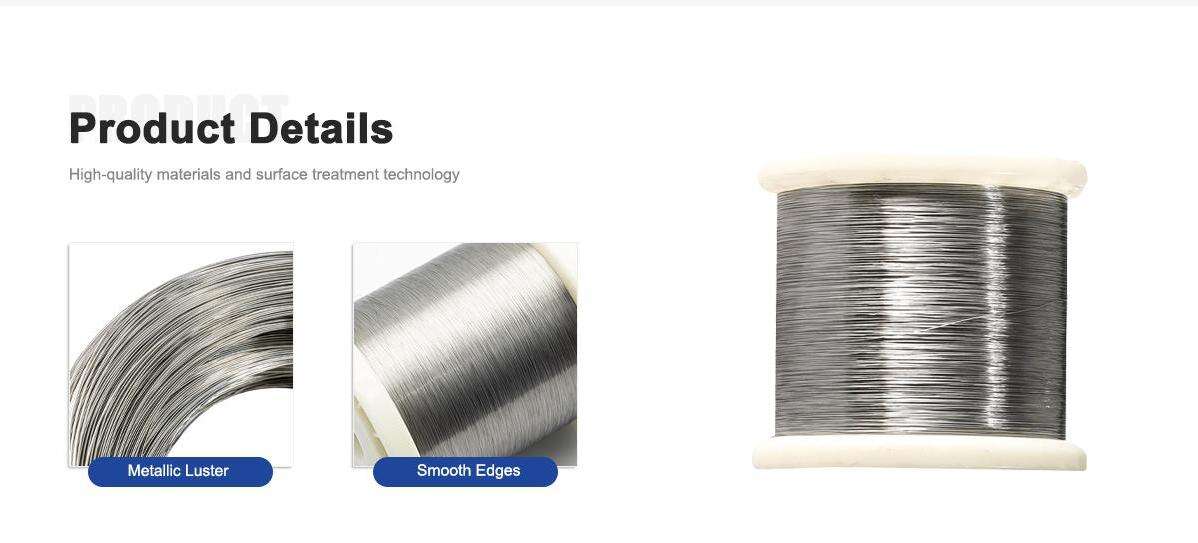

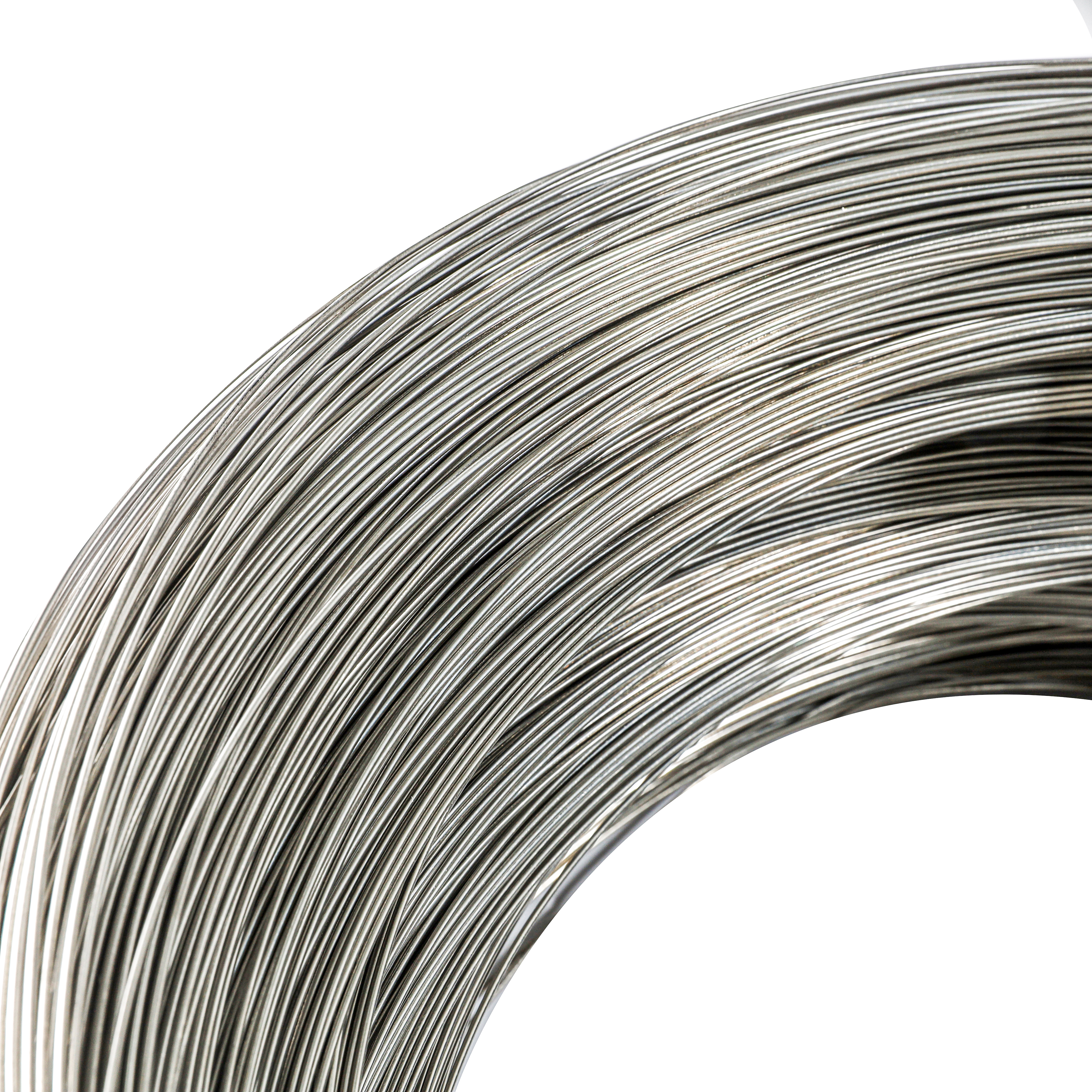

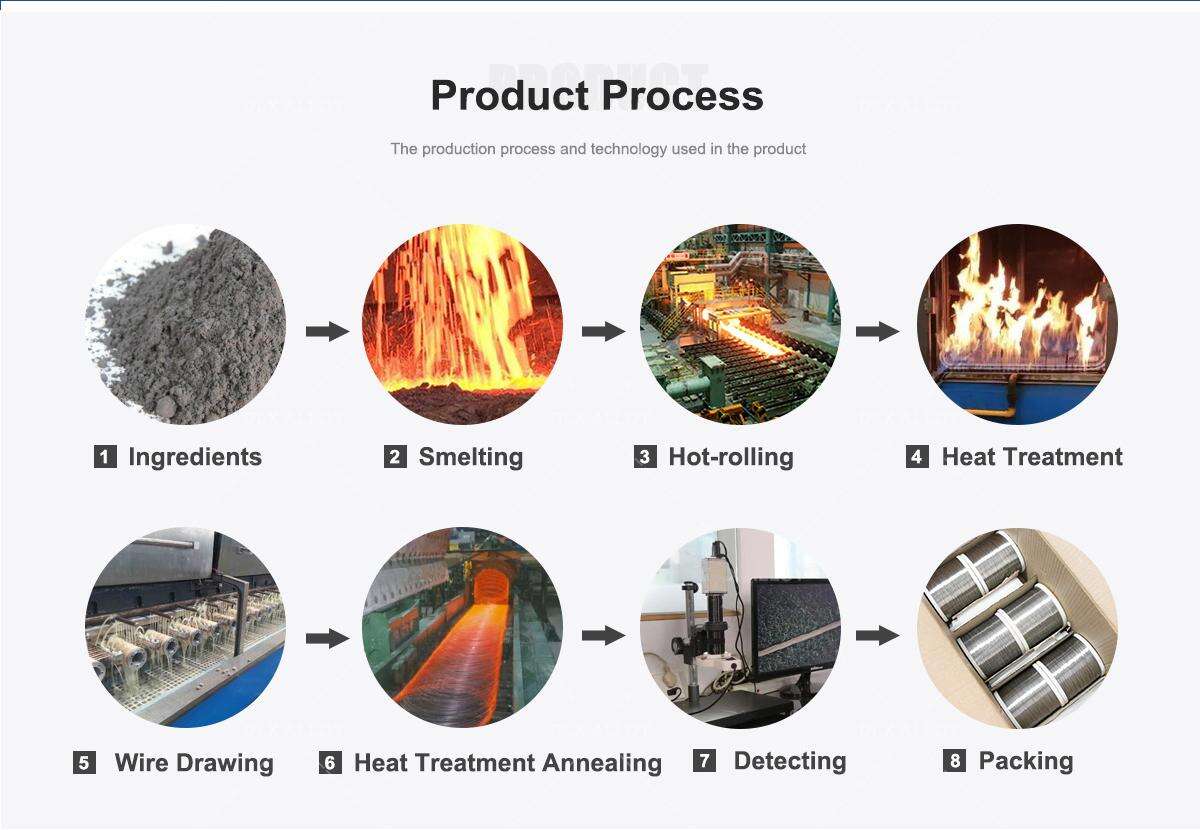

Our High-Resistivity Wire NiCr 80/20 is a top-grade nichrome alloy designed specifically for applications requiring robust oxidation resistance and stable electrical properties. This oxidation-proof wire excels in chemical processing, offering unmatched durability against corrosive elements while maintaining high resistivity for efficient heating. Ideal for industries seeking reliable nichrome heating elements, this NiCr 80/20 wire ensures long-lasting performance in high-temperature settings, making it a preferred choice for electrical resistance wire solutions in furnaces, kilns, and laboratory equipment.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High Resistivity and Electrical Stability in Nichrome Heating Elements: Boasts a resistivity of approximately 1.09 μΩ·m, ideal for precise control in electrical resistance wire systems.

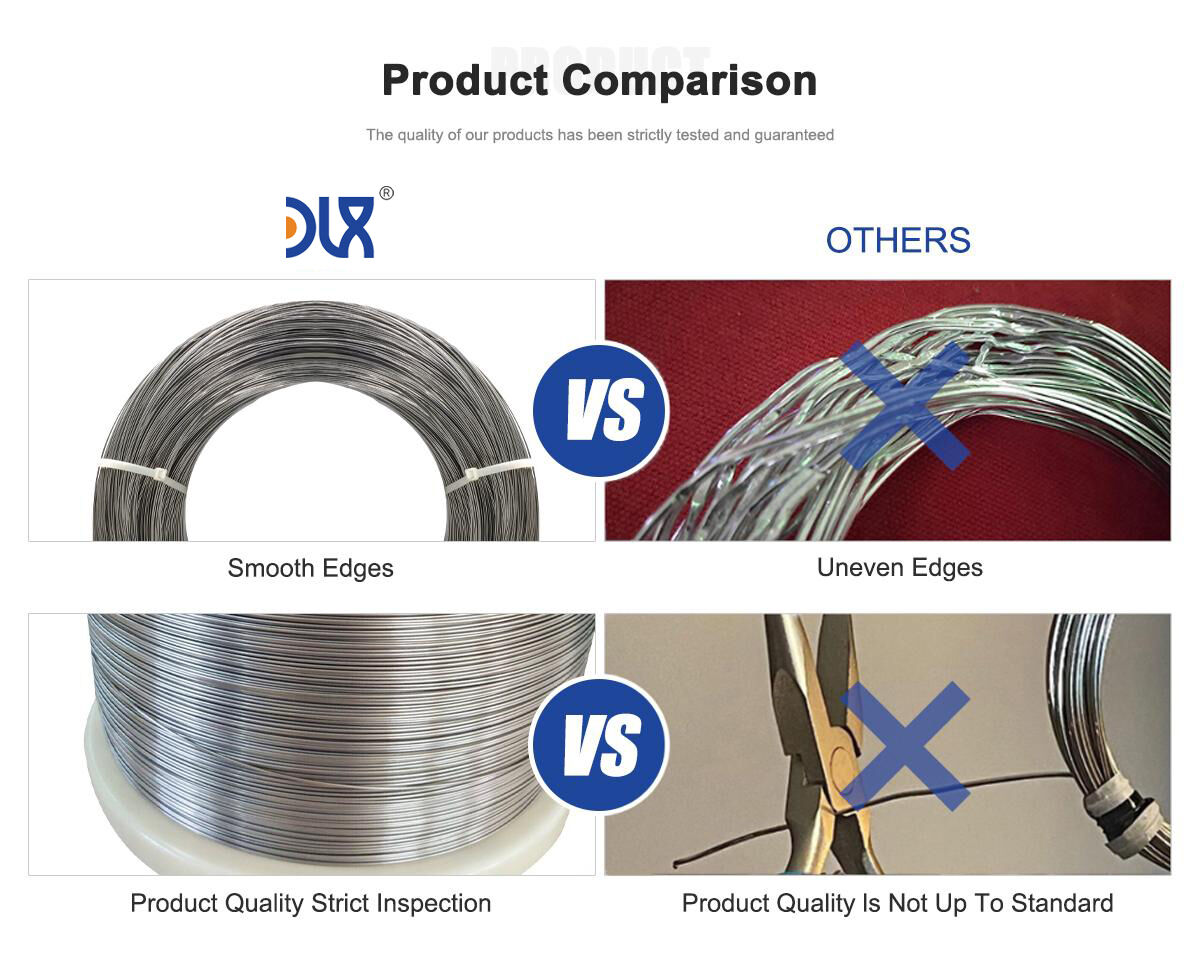

- Superior Oxidation Resistance for Chemical-Proof Wire Applications: Forms a protective oxide layer that prevents degradation, making it perfect for oxidation-proof environments in chemical processing.

- Excellent High-Temperature Performance in Alloy 80/20 Wire: Withstands temperatures up to 1200°C without losing structural integrity, suitable for demanding high-temperature wire uses.

- Corrosion and Chemical Resistance in Industrial Nichrome Wire: Resists acids, alkalis, and other corrosive agents, enhancing longevity in chemical-resistant wire setups.

- Flexible and Easy-to-Form NiCr Resistance Alloy: Available in various diameters for custom shaping into coils or elements, supporting versatile heating element wire designs.

- Long Service Life for Cost-Effective Electrical Wire Solutions: Minimizes replacement needs due to its robust nichrome alloy composition, offering value in high-resistivity applications.

Overview of High-Temperature Nichrome Wire NiCr 80/20:

The NiCr 80/20 high-resistivity wire represents a pinnacle in nichrome alloy technology, blending 80% nickel and 20% chromium for superior oxidation resistance and thermal stability. As a versatile electrical resistance wire, it is oxidation-proof even in aggressive chemical atmospheres, providing consistent high resistivity up to 1200°C. This overview highlights its role in enhancing efficiency for heating element wire applications, from industrial furnaces to precision lab instruments, ensuring optimal performance in high-temperature wire scenarios where reliability is paramount.

Features of Durable NiCr 80/20 Resistance Wire:

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Applications of Oxidation-Proof NiCr 80/20 Wire:

- Industrial Furnaces and Kilns with Nichrome Heating Elements: Essential for uniform heating in metalworking and ceramics, leveraging its high-temperature wire capabilities.

- Chemical Processing Equipment Using Resistance Wire Alloys: Provides reliable performance in reactors and distillation units, where oxidation-proof and chemical-resistant wire is crucial.

- Laboratory and Scientific Instruments for Electrical Resistance Wire: Ideal for precise temperature control in ovens, incubators, and analytical devices requiring stable nichrome wire.

- Aerospace and Automotive High-Temperature Applications: Supports sensor and ignition systems with durable NiCr 80/20 alloy for extreme conditions.

- Household Appliances Featuring Oxidation-Resistant Heating Wire: Used in toasters, hair dryers, and space heaters for safe, efficient high-resistivity operation.

- Electronics and Sensor Manufacturing with Chemical-Proof Nichrome Wire: Enhances reliability in resistive sensors and probes exposed to harsh environments.

FAQ on High-Resistivity Nichrome Wire NiCr 80/20:

1.What makes NiCr 80/20 resistance wire suitable for high-temperature heating element applications?

The alloy's high resistivity and oxidation-proof properties ensure stable performance at elevated temperatures, making it a go-to for nichrome heating elements in industrial settings.

2.How does the oxidation resistance of this electrical wire compare to other nichrome alloys?

NiCr 80/20 excels with a self-forming protective layer, offering superior oxidation-proof capabilities over standard alloys, especially in chemical-resistant wire scenarios.

3.Can this high-resistivity wire be used in corrosive chemical environments?

Yes, its chemical-proof design resists oxidation and corrosion, ideal for applications in aggressive chemical processing with durable NiCr alloy wire.

4.What diameters are available for NiCr 80/20 high-temperature wire?

We offer a range from 0.1mm to 5mm, customizable for various electrical resistance wire needs in heating and industrial uses.

5.Is this oxidation-resistant nichrome wire compliant with industry standards?

Absolutely, it meets ASTM and ISO specifications for high-resistivity alloys, ensuring quality in chemical and heating element wire applications.

6.How to install or coil the NiCr 80/20 alloy for optimal performance in resistance heating?

Use standard coiling techniques; ensure even spacing to maximize heat distribution in high-temperature wire setups, with guidance available for custom chemical-proof installations.