High Purity DLX Ni200 Pure Nickel Strip for Battery Welding

Our DLX Ni200 pure nickel strip is engineered from 99.6% high-purity nickel, offering exceptional conductivity and corrosion resistance ideal for battery welding tabs. This versatile nickel foil strip ensures strong, reliable connections in battery pack assembly, minimizing resistance and enhancing overall performance.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High Purity Composition (99.6% Nickel): Ensures low electrical resistance and superior conductivity for efficient battery welding strips and foil applications.

- Excellent Corrosion Resistance: Protects against oxidation in humid or acidic environments, ideal for long-term use in EV battery packs and power tool connectors.

- Superior Ductility and Flexibility: Allows easy forming into custom shapes for precise battery tab welding without cracking or brittleness.

- Thermal Stability for Welding: Withstands high temperatures during spot welding processes, reducing defects in nickel foil battery assembly.

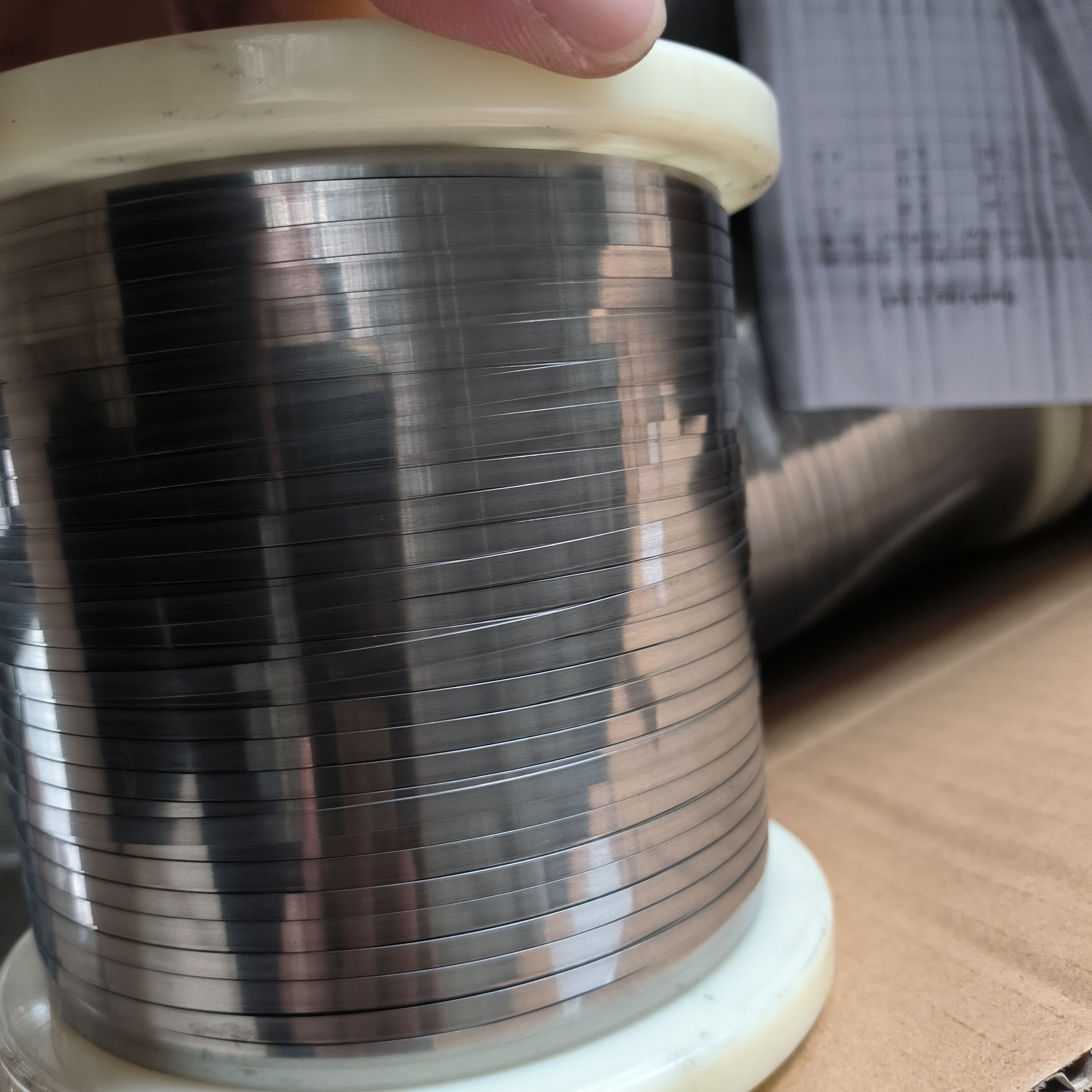

- Customizable Dimensions: Available in various thicknesses (0.1mm-0.5mm) and widths to suit diverse battery pack designs and manufacturing needs.

- Low Magnetic Permeability: Minimizes interference in sensitive electronic applications, enhancing performance in consumer battery welding tabs.

- Eco-Friendly and Compliant: Meets RoHS standards, supporting green manufacturing in global nickel strip for battery markets.

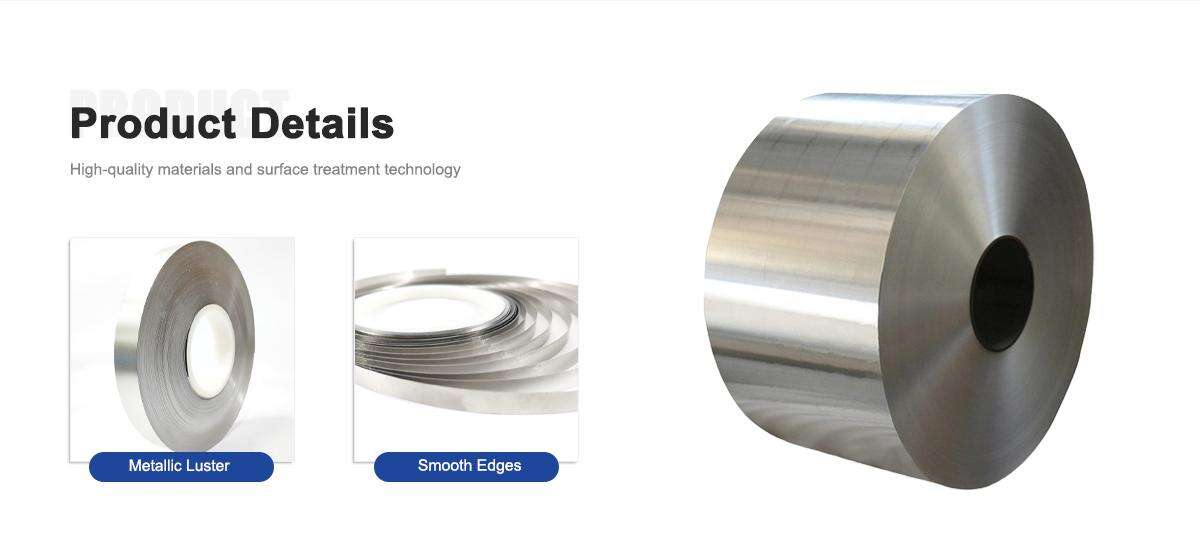

Discover the excellence of DLX Ni200 high purity nickel strip, a top-choice material for battery welding and connector solutions. This overview highlights how our pure nickel foil tabs provide unmatched electrical conductivity and mechanical strength, making them essential for modern battery technologies. From lithium-ion cell assembly to large-scale EV battery packs, Ni200 strips facilitate precise spot welding, ensuring minimal voltage drop and enhanced cycle life. Explore the benefits of using high-purity nickel in your projects, including resistance to corrosion in harsh environments and compatibility with various welding techniques like laser and ultrasonic methods. Ideal for manufacturers seeking reliable battery tab materials, this Ni200 strip supports sustainable energy solutions worldwide.

Key Advantages of High Purity DLX Ni200 Nickel Strip

Why Choose Our Ni200 Nickel Strip?

✔ High Purity for Stable Performance & Long Battery Life

✔ Custom Width & Thickness Available for Large Orders

✔ Competitive Factory Pricing & Reliable Bulk Supply

✔ Fast Global Shipping & OEM Support

| Specification | Details |

|---|---|

| Material | Ni200 Pure Nickel (≥99.6%) |

| Thickness | 0.15mm (Customizable) |

| Width | 2mm – 300mm (Customizable) |

| Standard Compliance | ASTM B162, GB/T 2054-2005 |

| Melting Point | 1435°C (2615°F) |

| Tensile Strength | ≥380 MPa |

| Electrical Resistivity | ≤0.099 Ω·mm²/m |

Why Choose Our Ni200 Nickel Strip?

✔ High Purity for Stable Performance & Long Battery Life

✔ Custom Width & Thickness Available for Large Orders

✔ Competitive Factory Pricing & Reliable Bulk Supply

✔ Fast Global Shipping & OEM Support

Applications of DLX Ni200 Pure Nickel Strip in Battery Welding

- Electric Vehicle (EV) Battery Packs: Essential for connecting cells in high-capacity lithium-ion batteries, providing reliable welding tabs for extended range and safety.

- Power Tools and Cordless Devices: Used in battery assembly for drills, saws, and vacuums, where pure nickel strips ensure durable spot welding connections.

- Consumer Electronics: Ideal for laptops, smartphones, and wearables, offering high-purity nickel foil for compact battery designs with minimal resistance.

- Renewable Energy Storage: Supports solar and wind battery systems with corrosion-resistant Ni200 strips for efficient energy transfer and longevity.

- Medical Devices: Applied in portable medical equipment batteries, where precision welding and biocompatibility are critical for reliable performance.

- Aerospace and Defense: Utilized in high-reliability battery packs requiring thermal-stable nickel tabs for extreme conditions.

- Custom Manufacturing: Versatile for DIY battery rebuilding and prototyping, enabling seamless integration in various welding applications.

FAQs:Common Questions on High Purity DLX Ni200 Nickel Strip for Battery

1.What is the purity level of DLX Ni200 pure nickel strip for battery welding?

Our Ni200 nickel strip boasts 99.6% purity, ensuring optimal conductivity and resistance to impurities in battery tab applications.

2.How does Ni200 high purity nickel strip improve battery pack assembly?

It provides low-resistance connections via spot welding, enhancing efficiency and cycle life in lithium-ion and EV battery welding processes.

3.Is DLX Ni200 nickel foil suitable for laser welding in battery manufacturing?

Yes, its thermal stability and ductility make it compatible with laser, ultrasonic, and resistance welding techniques for precise battery tabs.

4.What dimensions are available for pure nickel strips in battery applications?

We offer customizable options, typically ranging from 0.1mm to 0.5mm thickness and 3mm to 10mm width, tailored for various battery welding needs.

5.Can Ni200 nickel strip withstand corrosion in harsh battery environments?

Absolutely, its high-purity composition resists oxidation and corrosion, making it ideal for long-term use in power tool and consumer electronics batteries.

6.How to store DLX high purity nickel strip for optimal battery welding performance?

Keep in a dry, cool environment away from moisture to prevent surface oxidation, ensuring ready-to-use quality for battery pack assembly.