High Performance Superelastic Nitinol Wire For Guidewires & Forming

Premium Superelastic Nitinol Wire – Nickel Titanium Alloy for Medical Guidewires, Stents, and Precision Forming Mandrels

- Overview

- Specification

- Features & Applications

- FAQs

- Recommended Products

Product Overview: Superelastic Nitinol Wire for Guidewires and Medical Device Forming

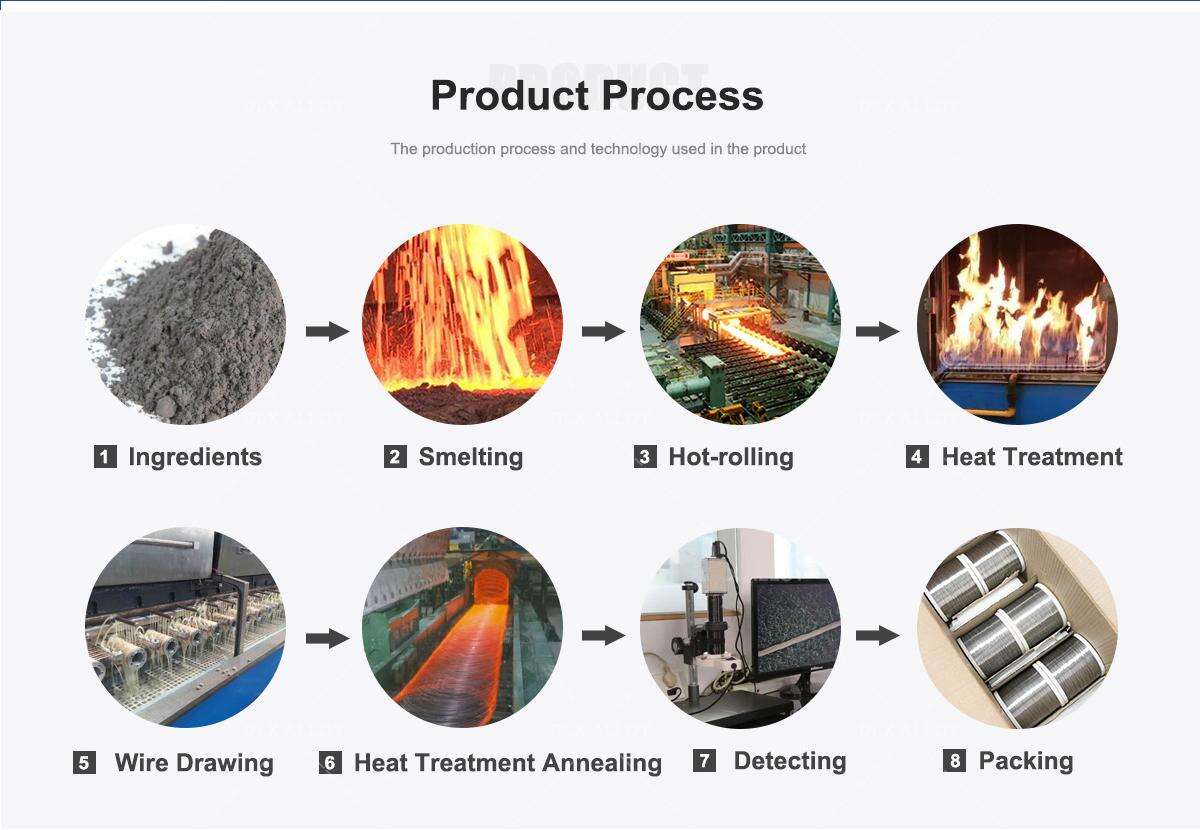

Discover our high-performance superelastic nitinol wire, engineered from premium nickel-titanium alloy (NiTi) for exceptional flexibility and durability. This shape memory alloy wire offers superior superelasticity, allowing it to withstand up to 8% strain without permanent deformation, making it ideal for demanding medical device applications.

Our high-performance superelastic nitinol wire is a advanced nickel titanium shape memory alloy designed specifically for critical medical applications like guidewires, stents, stylets, and forming mandrels. Exhibiting outstanding superelastic properties at room and body temperature (Af typically below 37°C), this NiTi alloy wire delivers unparalleled flexibility, enabling navigation through tortuous pathways without kinking – unlike traditional stainless steel. With superior fatigue resistance, biocompatibility, and the ability to recover from significant deformation, it supports innovative minimally invasive devices such as vascular stents, orthopedic implants, and stone retrieval baskets. Ideal for manufacturers seeking reliable nitinol wire for medical guidewires and precision shape-setting processes.

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

Key Features of Superelastic Nitinol Alloy Wire

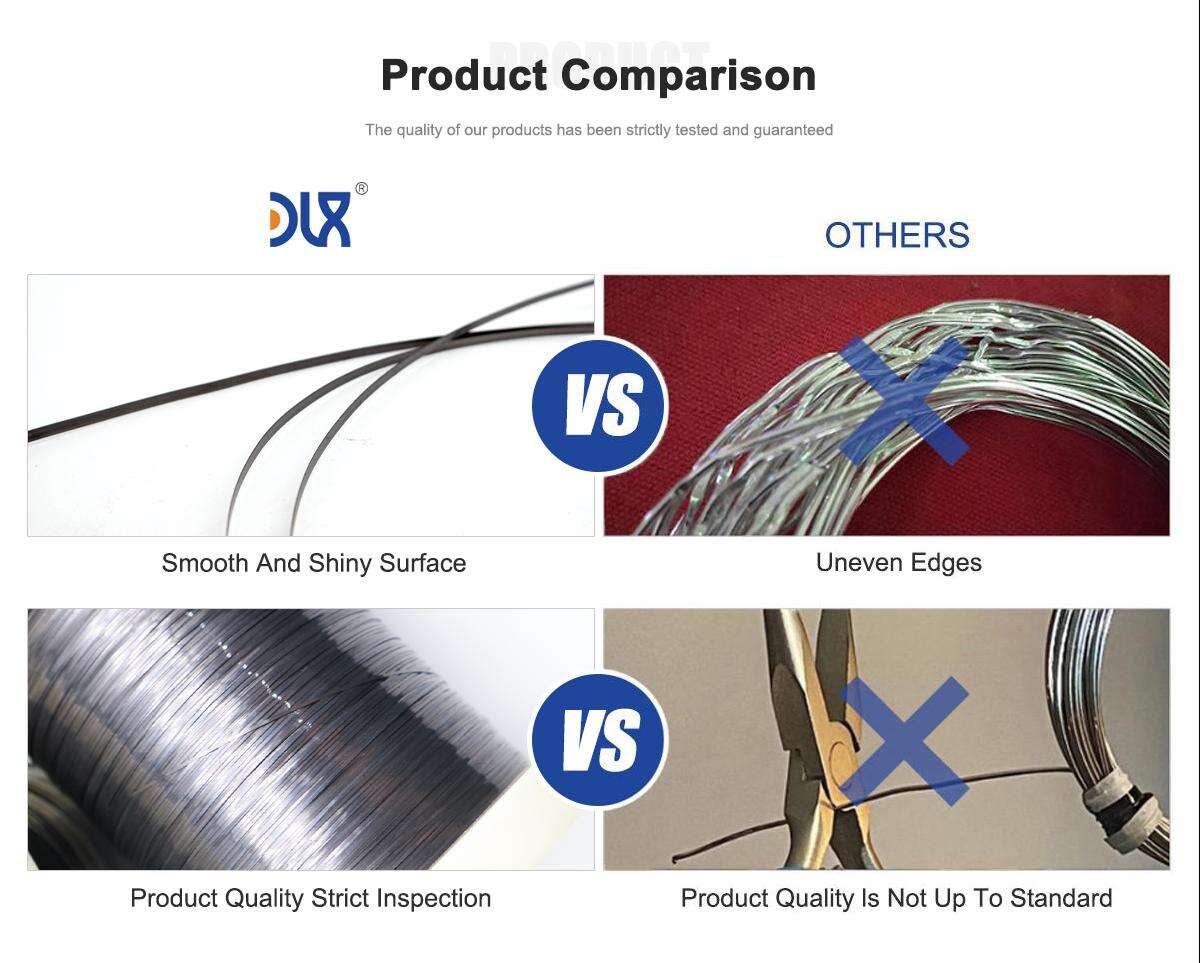

- Superelasticity and Shape Memory Effect: Recovers up to 8-10% strain with minimal hysteresis, ensuring kink-resistant performance in medical guidewires and self-expanding stents.

- Excellent Biocompatibility: ASTM F2063 compliant nickel-titanium composition minimizes adverse reactions, suitable for long-term implants like vascular devices and orthodontic archwires.

- High Fatigue and Corrosion Resistance: Outperforms stainless steel in cyclic loading and harsh environments, extending device lifespan in applications such as forming mandrels and stylets.

- Superior Torqueability and Flexibility: Provides precise control and smooth navigation in complex anatomies, essential for nitinol guidewire cores and endovascular procedures.

- Customizable Specifications: Available in straight annealed forms with light oxide surfaces, various diameters, and tunable transformation temperatures for optimal NiTi wire forming and medical device integration.

Applications of High-Performance Nitinol Wire in Medical Devices

This versatile superelastic NiTi wire excels in a range of biomedical and industrial uses:

- Medical Guidewires and Core Wires: Enables safe passage through tortuous vessels with exceptional kink resistance and torque response.

- Self-Expanding Stents and Vascular Implants: Leverages shape memory for minimally invasive deployment and radial strength.

- Forming Mandrels and Shape-Setting Tools: Ideal for precision manufacturing of coils, baskets, and complex geometries in device production.

- Orthopedic and Endodontic Devices: Used in stylets, stone retrieval baskets, and files for enhanced flexibility and durability.

- Other Innovations: Supports robotic actuators, orthodontic archwires, and emerging minimally invasive surgical instruments requiring reliable nitinol alloy performance.

1.What is superelastic nitinol wire?

Superelastic nitinol is a nickel-titanium shape memory alloy that exhibits remarkable elasticity at body temperature, allowing it to deform significantly and return to its original shape without permanent damage – ideal for medical guidewires and stents.

2.What are the main advantages over stainless steel?

Unlike stainless steel, our high-performance nitinol wire offers superior kink resistance, biocompatibility, and up to 8% recoverable strain, reducing procedural risks in tortuous pathways and improving patient outcomes.

3.Is this nitinol wire biocompatible for implants?

Yes, it meets ASTM F2063 standards for surgical implants, with excellent corrosion resistance and minimal nickel release, making it safe for long-term use in vascular stents and guidewires.

4.What diameters and finishes are available?

We offer customizable diameters (typically 0.001" to 0.040") with light oxide, etched, or polished surfaces for optimal performance in nitinol forming mandrels and medical applications.

5.Can this wire be used for shape-setting?

Absolutely – its shape memory properties make it perfect for heat-treated forming in stents, baskets, and custom medical devices.

6.What is the typical transformation temperature?

Superelastic grades have Af temperatures below body temperature (around -20°C to 22°C), ensuring full superelasticity during procedures. Custom Af tuning available upon request.