FeCrAl Resistance Wire 0Cr25Al5 - High Temperature Heating Element Alloy

Discover our oxidation resistant FeCrAl wire 0Cr21Al6, a high-performance electric resistance heating coil designed for demanding industrial environments. This FeCrAl alloy wire offers exceptional heat resistance up to 1250°C, making it perfect for applications requiring reliable electric heating elements. Engineered with a unique composition of iron, chromium, and aluminum, the 0Cr21Al6 wire forms a protective oxide layer that prevents degradation, ensuring longevity in oxidative atmospheres.

- Overview

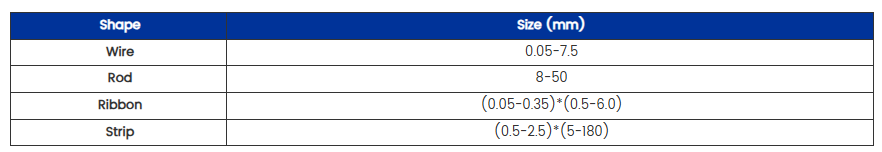

- Specification

- Applications

- FAQs

- Recommended Products

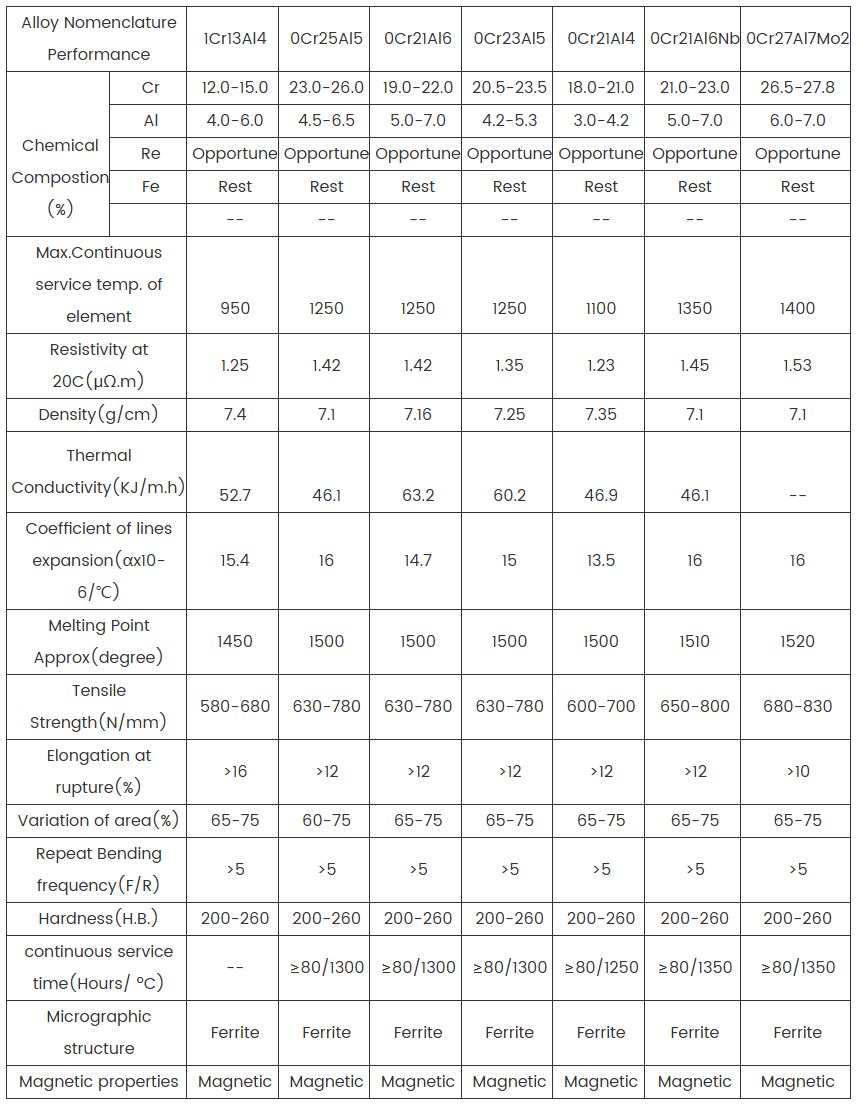

- High-Temperature Stability in FeCrAl Heating Coils: Withstands continuous operation up to 1250°C, making it superior for electric heating elements in extreme conditions.

- Enhanced Oxidation Resistance for Resistance Wire Applications: Forms a stable alumina oxide layer, protecting the 0Cr21Al6 alloy from corrosion in oxidative and high-heat environments.

- Optimal Electrical Resistivity in Electric Resistance Heating Wire: Provides consistent resistance values (around 1.42 Ω·mm²/m), ensuring efficient power conversion for heating coil designs.

- Low Thermal Expansion for Durable Furnace Wire: Minimizes deformation and cracking, ideal for long-term use in kilns and radiant heaters.

- Customizable Diameters and Forms for Versatile FeCrAl Wire Usage: Available in spools, coils, or straight lengths, supporting diverse industrial heating element needs.

- Eco-Friendly and Cost-Effective High-Temperature Wire Solution: Lead-free composition with high yield strength, reducing replacement frequency in electric furnace applications.

✓ Product Description

The 0Cr21Al6 FeCrAl wire is a specialized electric resistance heating coil renowned for its oxidation resistance and high-temperature capabilities. As a leading FeCrAl alloy wire in the resistance heating wire market, it excels in environments where standard materials fail due to corrosion or heat stress. This overview highlights its role in modern industrial heating systems, from basic electric heating elements to advanced furnace wire applications. With a melting point exceeding 1500°C and excellent mechanical strength, the 0Cr21Al6 heating coil is engineered for durability and efficiency. Ideal for global industries seeking reliable high-temperature wire solutions, it supports seamless integration into various electric resistance setups, promoting energy savings and reduced maintenance costs.

✓ Product Features

Key Features & Advantages ofOxidation Resistant FeCrAl Alloy Wire 0Cr21Al6

✓ Product Applications

Industrial & Commercial Applications of 0Cr21Al6 FeCrAl Wire in Electric Heating Coils

- Industrial Furnaces and Kilns with Oxidation Resistant Heating Elements: Essential for metallurgy and ceramics processing, where high-temperature FeCrAl alloy wire ensures uniform heat distribution.

- HVAC Systems and Radiant Heaters Using Electric Resistance Wire: Provides reliable performance in space heaters and underfloor heating, leveraging the 0Cr21Al6 coil's durability.

- Household Appliances Featuring High-Temperature Heating Coils: Ideal for toasters, ovens, and dryers, offering safe and efficient electric heating solutions.

- Automotive and Aerospace Components with FeCrAl Resistance Heating: Used in exhaust systems and sensor heaters, benefiting from the wire's oxidation resistance in harsh conditions.

- Laboratory Equipment and Scientific Instruments: Supports precise temperature control in incubators and test chambers with stable 0Cr21Al6 electric resistance heating.

- Energy Sector Applications for Furnace Wire and Heating Elements: Employed in power generation and renewable energy setups requiring robust high-temperature wire.

✓ Product FAQ - FeCrAl Wire 0Cr21Al6 Electric Resistance Heating Coil

1.What is the maximum operating temperature for the 0Cr21Al6 FeCrAl alloy wire in electric heating elements?

The 0Cr21Al6 resistance heating wire can operate continuously at up to 1250°C, with short-term peaks higher, depending on the environment and application in high-temperature heating coils.

2.How does the oxidation resistance work in this FeCrAl resistance wire?

The wire forms a protective aluminum oxide layer on its surface, which acts as a barrier against further oxidation, making it ideal for prolonged use in oxidative atmospheres like furnaces and kilns.

3.Can the 0Cr21Al6 electric heating coil be customized for specific resistance heating applications?

Yes, we offer customization in wire diameter (from 0.05mm to 10mm), length, and form to suit various electric resistance heating needs, including coiled or straight configurations.

4.What are the electrical properties of this high-temperature FeCrAl wire?

It features a resistivity of approximately 1.42 μΩ·m, low temperature coefficient, and high tensile strength, ensuring efficient performance in electric furnace wire and heating element designs.

5.Is the 0Cr21Al6 oxidation resistant wire suitable for outdoor or corrosive environments?

Absolutely, its superior corrosion resistance makes it perfect for outdoor heaters or industrial settings with moisture and chemicals, outperforming standard resistance heating wires.

6.How do I install the FeCrAl heating coil in my system?

Installation involves securing the wire in insulated supports, ensuring proper tension to avoid sagging at high temperatures. Consult our technical guide for best practices in electric resistance heating setups.