Durable NiCr 60/15 Nichrome Wire for Electric Furnace and Appliance Use

Discover our durable NiCr 60/15 nichrome wire, a top-choice resistance heating wire engineered for high-temperature performance in electric furnace heating elements and appliance repair. This nichrome alloy wire offers exceptional oxidation resistance and longevity, making it ideal for demanding applications like kiln heating wire and toaster heating elements.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

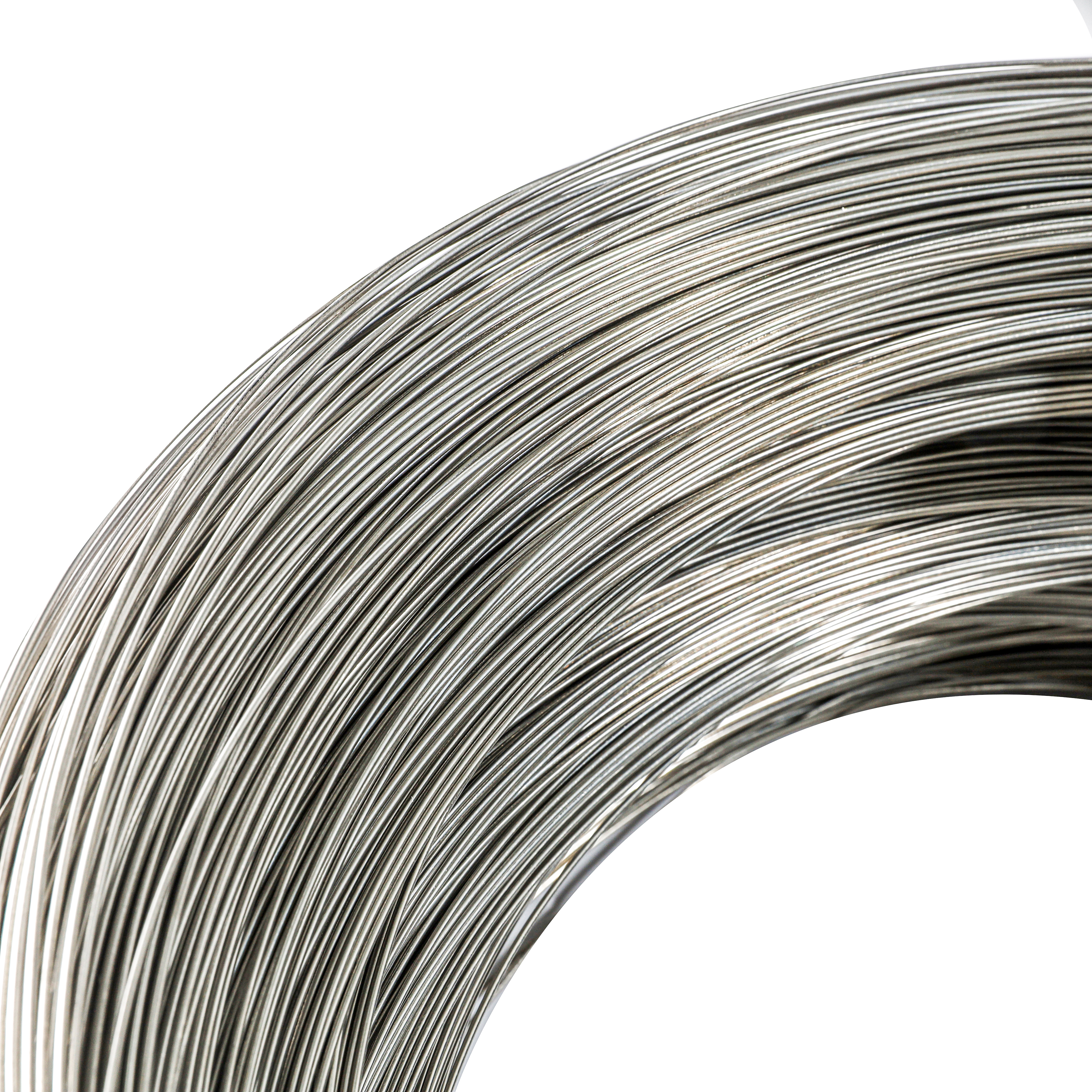

- Superior Heat Resistance in Nichrome Wire for Furnace Applications: Withstands temperatures up to 1150°C, ideal for long-term use in electric furnace heating wire and high-heat appliance environments.

- Excellent Oxidation and Corrosion Resistance in Resistance Heating Wire: The NiCr 60/15 composition forms a protective oxide layer, extending the life of nichrome alloy wire in humid or aggressive industrial settings.

- High Electrical Resistivity for Efficient Heating Element Wire: Offers stable resistance values, ensuring precise temperature control in kiln wire and toaster element wire setups.

- Durable Mechanical Strength in Nichrome Heating Wire: Resistant to deformation and breakage, perfect for coiled configurations in appliance repair wire and laboratory heating systems.

- Versatile Gauge Options for Custom Electric Furnace Wire: Available in various diameters to suit specific resistance wire needs, from fine appliance coil wire to robust industrial heating applications.

- Eco-Friendly and RoHS Compliant Nichrome Resistance Wire: Manufactured with sustainable practices, free from harmful substances, supporting green heating solutions worldwide.

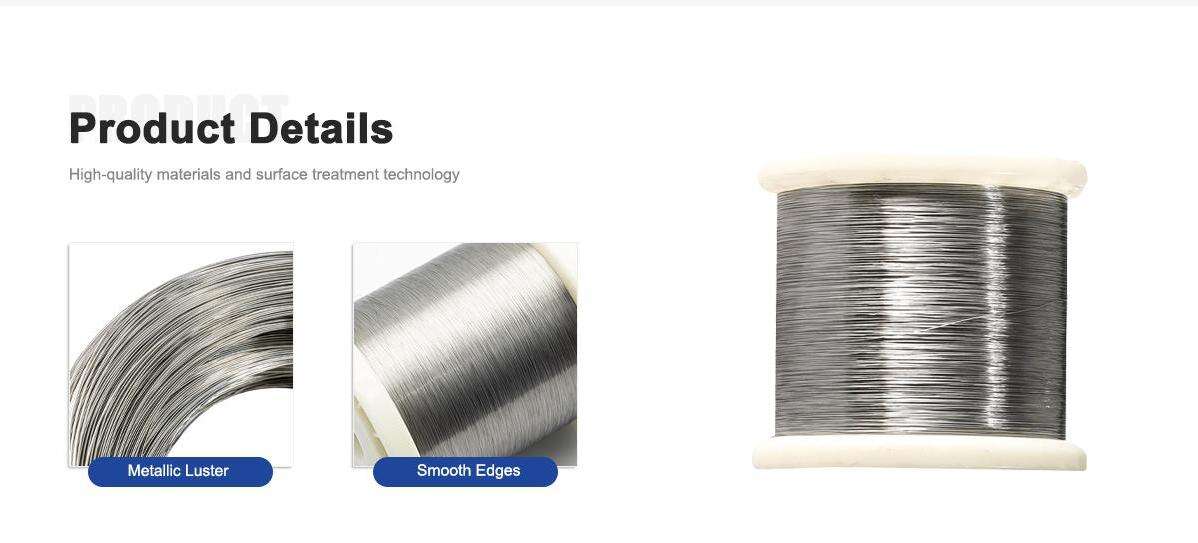

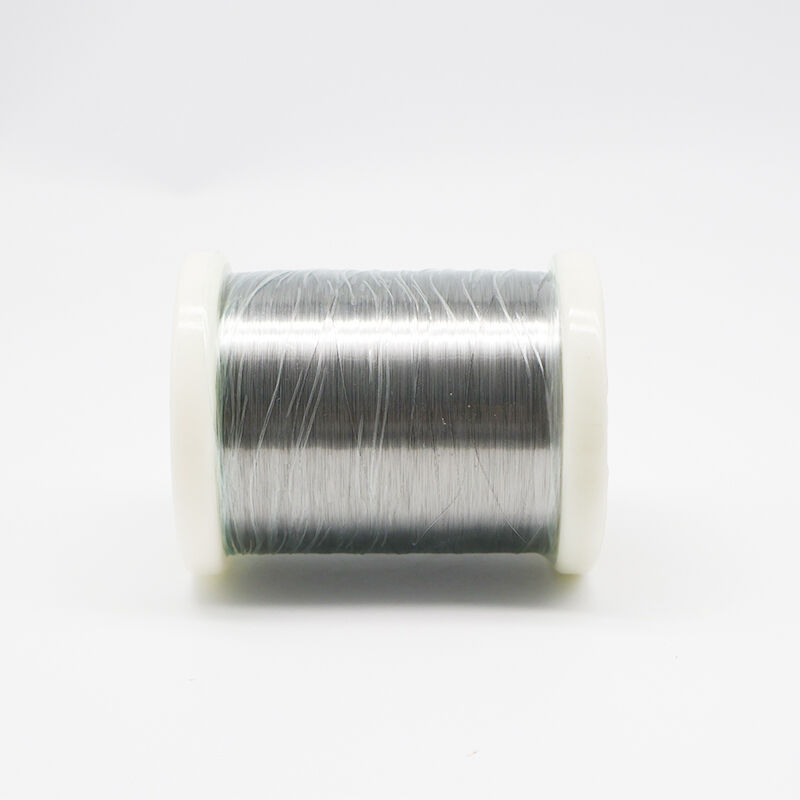

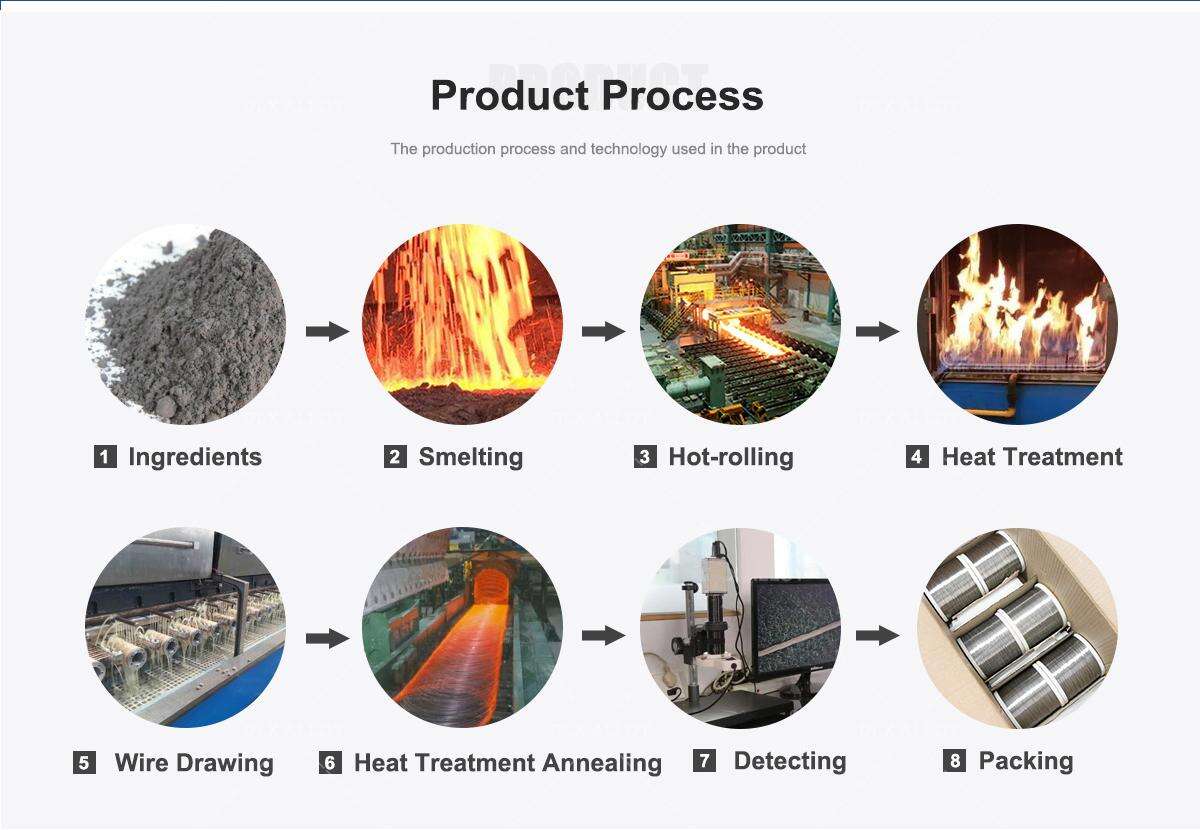

Overview of Durable NiCr 60/15 Nichrome Resistance Wire

Our NiCr 60/15 nichrome wire is a premium nickel-chromium alloy resistance wire specifically formulated with 60% nickel and 15% chromium for outstanding durability and thermal stability. As a leading heating element wire, it excels in environments requiring consistent high-temperature resistance up to 1150°C, preventing sagging or failure in electric furnace wire configurations and appliance heating systems. This versatile nichrome heating wire is widely used in industrial heating wire solutions and household appliance wire replacements, offering corrosion-resistant properties that enhance lifespan in oxidative atmospheres. Whether for laboratory furnace elements or commercial oven wire, it provides reliable performance with low thermal expansion, making it a staple in global heating technology sectors from manufacturing hubs in China to engineering firms in Germany.

Key Features of High-Performance NiCr 60/15 Nichrome Alloy Wire

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Applications of Reliable NiCr 60/15 Nichrome Wire

- Electric Furnace and Kiln Heating Wire: Essential for high-temperature processes in ceramic kilns, metal annealing furnaces, and laboratory ovens, providing uniform heat distribution.

- Household Appliance Repair and Heating Elements: Used in toasters, hair dryers, space heaters, and electric stoves for dependable nichrome coil wire performance.

- Industrial Heating Systems with Nichrome Alloy Wire: Ideal for resistance heating in manufacturing equipment, such as plastic molding machines and heat sealing devices across US and European factories.

- Laboratory and Scientific Equipment Resistance Wire: Supports precise temperature control in incubators, sterilizers, and analytical instruments in research facilities globally.

- Custom Heating Coil Applications in Appliance Wire: Perfect for DIY projects or OEM integrations in radiant heaters and vaping devices requiring durable high-temperature wire.

- Commercial Oven and Food Processing Heating Elements: Ensures consistent baking and drying in professional kitchens and food industry setups in Asia-Pacific regions.

FAQ: Common Questions About Durable NiCr 60/15 Nichrome Resistance Wire

1.What is NiCr 60/15 nichrome wire and how does it differ from other resistance heating wires?

NiCr 60/15 is a nickel-chromium alloy wire with 60% nickel and 15% chromium, offering better heat resistance and longevity compared to standard nichrome grades like NiCr 80/20, making it suitable for moderate-temperature electric furnace wire and appliance applications without excessive power consumption.

2.How do I select the right gauge for my electric furnace heating element or appliance repair wire?

Choose based on required resistance and current load; finer gauges (e.g., 0.1-0.5mm) suit low-power appliance heating wire, while thicker ones (1-2mm) are better for high-wattage kiln heating wire. Consult our specifications for precise calculations in your local market.

3.Is this nichrome alloy wire suitable for high-temperature environments in industrial heating systems?

Yes, it handles up to 1150°C with excellent oxidation resistance, ideal for continuous operation in electric furnace elements and resistance coil wire in global industrial settings like those in Japan or the UK.

4.Can NiCr 60/15 nichrome heating wire be used outdoors or in humid conditions for appliance applications?

While highly corrosion-resistant, it's best for indoor or enclosed setups; for outdoor appliance wire, consider additional insulation to maintain performance in varying climates.

5.What maintenance is required for nichrome resistance wire in electric furnace and kiln applications?

Regularly inspect for oxidation buildup and clean gently; avoid mechanical stress to prolong life in heating element wire configurations, ensuring safety in professional installations worldwide.