DTi-6Al-4V Grade 5 Titanium Alloy Wire | High Strength

Premium Ti-6Al-4V (Grade 5) Titanium Alloy Wire – Alpha-Beta Alloy with Superior Strength-to-Weight Ratio and Excellent Corrosion Resistance

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

- High tensile strength (typically 895-1000 MPa) and yield strength for load-bearing components

- Excellent corrosion resistance in oxidizing and neutral environments

- Superior strength-to-weight ratio for weight-critical designs

- Good formability, weldability (using GTAW or similar methods), and heat treatability for customized properties

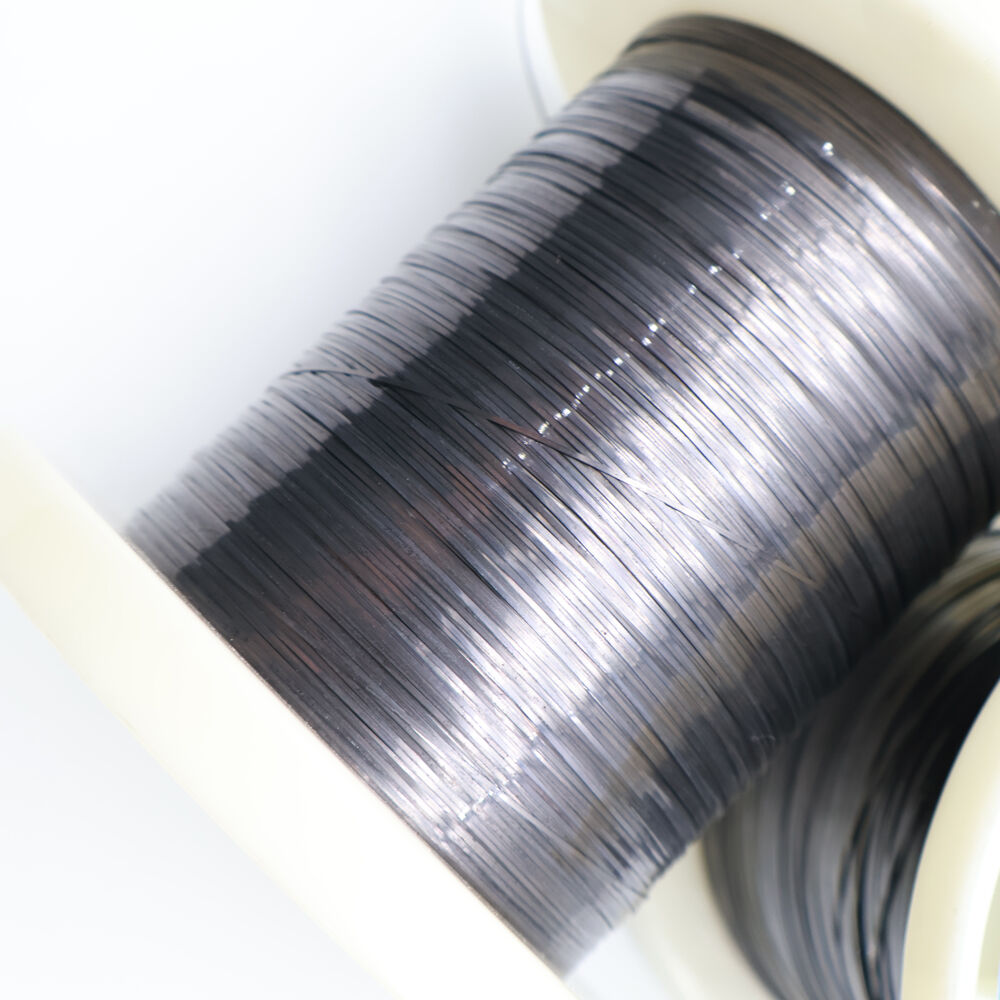

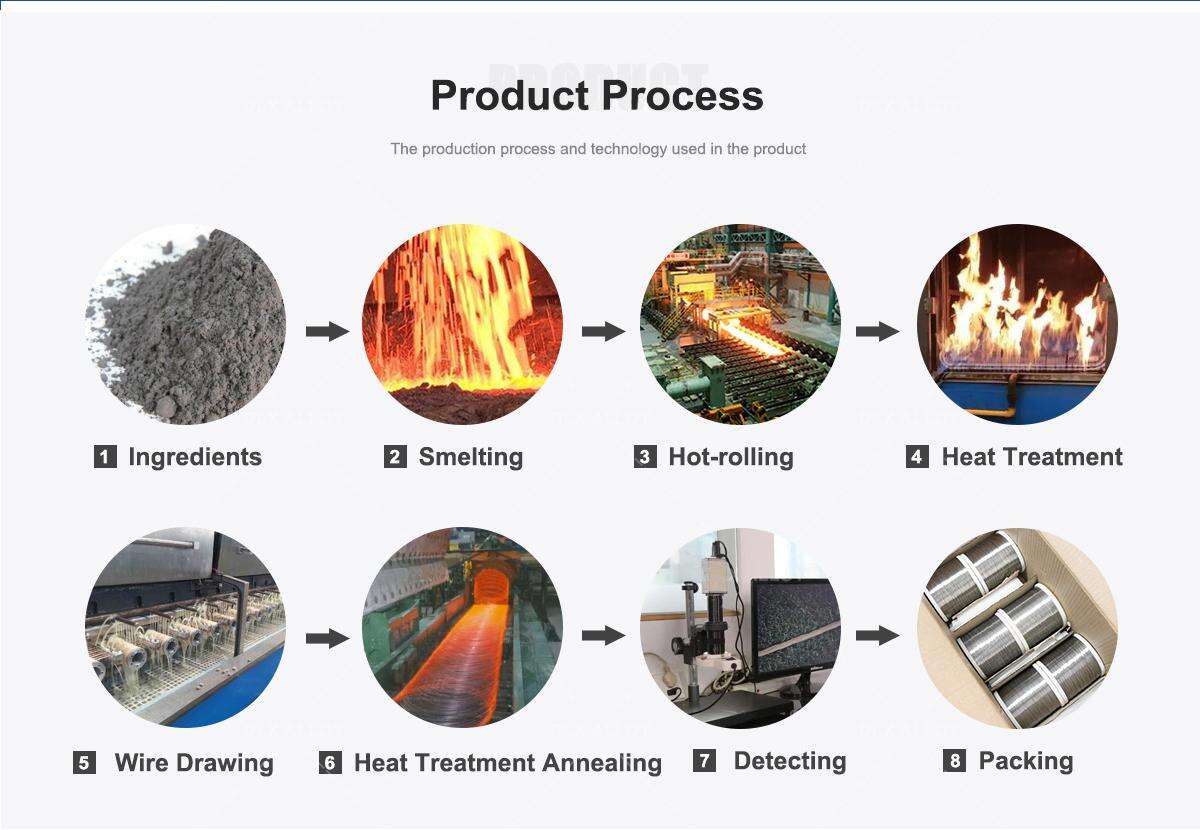

Product Overview : Ti-6Al-4V Grade 5 Titanium Alloy Wire

The Ti-6Al-4V (also known as Ti64 or ASTM Grade 5) titanium alloy wire is the workhorse of the titanium industry, accounting for nearly half of all titanium usage worldwide. This alpha-beta alloy combines the best attributes of strength, low density (approximately 4.43 g/cm³), and biocompatibility, making it a top choice for high-performance applications.

Key highlights include:

Whether for aerospace components, medical implants, or additive manufacturing, this Grade 5 titanium wire delivers unmatched durability and performance.

| Grade 1 Titanium Wire Chemical Composition | |||||||||

| Grade | N | C | H | Fe | O | AL | V | Pa | Mo |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | ||||

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | ||||

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | ||||

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | ||||

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | ||

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | |||

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 0.2-0.4 | |

Key Features of Ti-6Al-4V Grade 5 Titanium Alloy Wire

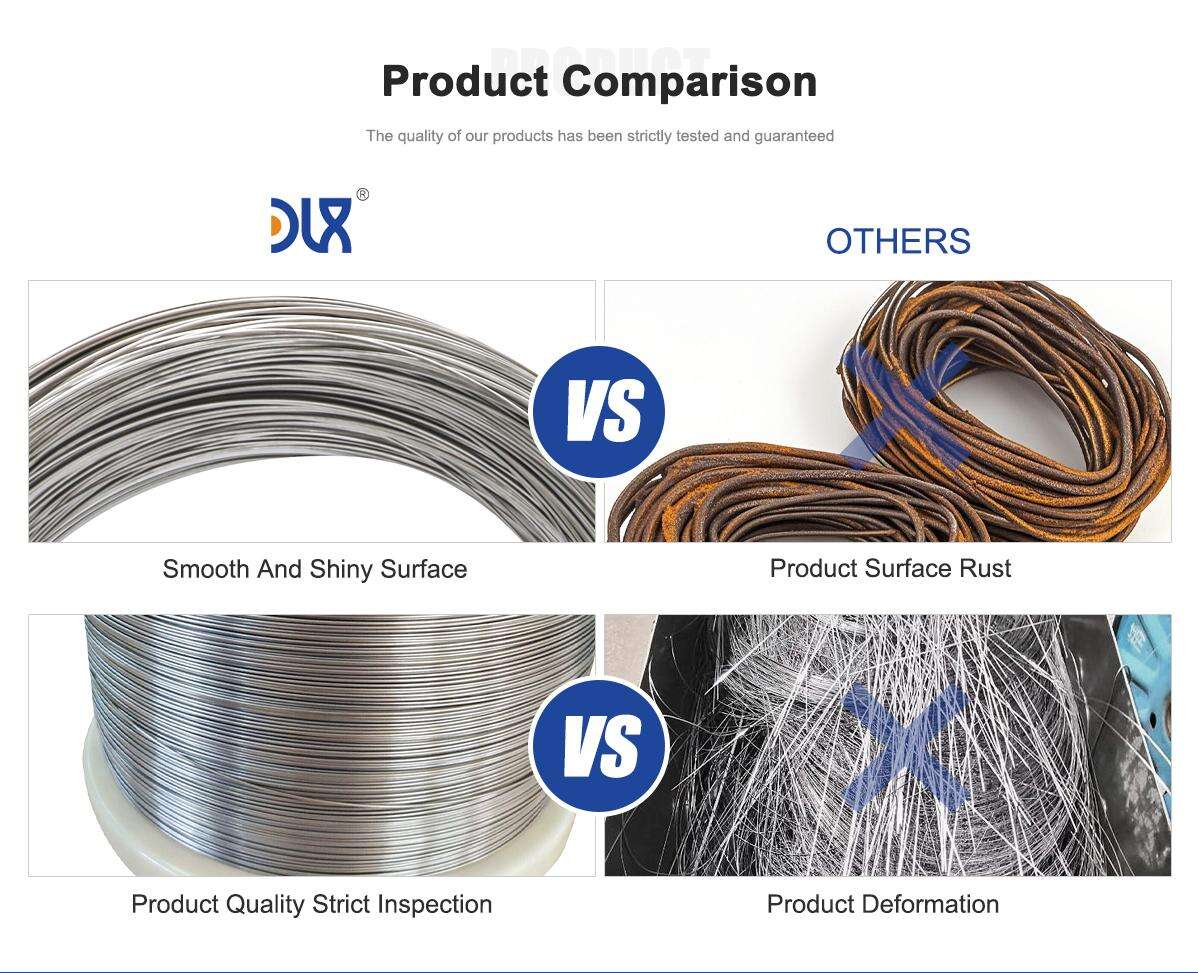

Our Ti-6Al-4V titanium alloy wire stands out with the following premium features:

- Exceptional High Strength and Fatigue Resistance: Superior tensile and yield strength with excellent performance under cyclic loading, ideal for aerospace fasteners and engine parts.

- Outstanding Corrosion Resistance: Forms a stable oxide layer for protection against seawater, chlorides, and chemical processing environments.

- Excellent Biocompatibility and Low Modulus: Preferred for medical and dental implants, offering compatibility with human tissue and reduced stress shielding.

- High Strength-to-Weight Ratio: Significantly lighter than steel while maintaining comparable strength, perfect for automotive springs, exhaust systems, and marine applications.

- Heat Treatable and Weldable: Can be solution treated and aged for enhanced properties; supports precise welding without compromising integrity.

- Versatile Temperature Performance: Maintains mechanical properties up to 400°C, suitable for elevated-temperature uses.

These attributes make our Grade 5 titanium wire a reliable, high-performance material for critical industries.

Applications of Ti-6Al-4V Grade 5 Titanium Alloy Wire

This versatile titanium alloy wire excels in a wide range of high-demand sectors:

- Aerospace and Aviation: Used in aircraft structural components, turbine blades, fasteners, and compressor parts for its lightweight strength and fatigue resistance.

- Medical and Biomedical: Essential for orthopedic implants, surgical instruments, dental devices, and prosthetic components due to superior biocompatibility.

- Automotive and Motorsports: Ideal for high-performance parts like valves, connecting rods, springs, and exhaust systems to reduce weight and improve durability.

- Marine and Offshore: Resists saltwater corrosion in equipment, fasteners, and structural elements.

- Chemical Processing and Oil & Gas: Handles harsh chemicals and environments in pumps, valves, and tubing.

- Additive Manufacturing and Welding: Popular as filler wire or feedstock for 3D printing complex, high-strength parts.

- Sports Equipment: Employed in lightweight frames and components for bicycles, golf clubs, and other performance gear.

1.What is Ti-6Al-4V Grade 5 titanium alloy wire?

Ti-6Al-4V (Grade 5) is an alpha-beta titanium alloy containing 6% aluminum and 4% vanadium. It is the most common titanium alloy, known for its high strength, corrosion resistance, and versatility in wire form.

2.What are the main properties of this titanium wire?

It offers high tensile strength (895+ MPa), excellent corrosion and fatigue resistance, low density, good weldability, and biocompatibility. It can be heat treated for further strength enhancement.

3.How does Grade 5 compare to commercially pure titanium?

Grade 5 is significantly stronger and more heat-treatable than pure grades (like Grade 2), while retaining similar corrosion resistance—making it ideal for structural and high-stress applications.

4.Is this wire suitable for medical implants?

Yes, Ti-6Al-4V Grade 5 has excellent biocompatibility and is widely used in orthopedic implants, though Grade 23 (ELI) is preferred for some extra-low interstitial requirements.