DLX NiTi Alloy Tube for Heart Valve Frames Medical Grade

Premium Medical Grade Nitinol Tube for Transcatheter Heart Valve Frames – Superelastic NiTi Alloy Tubing for Cardiovascular Implants

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

- Superelasticity for compression into low-profile delivery systems and reliable expansion at body temperature.

- Shape memory effect ensuring consistent performance in dynamic cardiac conditions.

- Outstanding biocompatibility and corrosion resistance for reduced thrombogenicity and enhanced patient safety.

Product Overview:Medical Grade Nitinol Tubing

Our DLX NiTi alloy tube represents the pinnacle of shape memory alloy technology for heart valve frame applications. Manufactured to stringent medical standards (ASTM F2063 compliant), this superelastic Nitinol tubing is engineered for transcatheter aortic valve implantation (TAVI) and other structural heart devices.

Key advantages include:

Widely used in self-expanding heart valve stents, this medical grade NiTi tubing supports minimally invasive procedures, improving outcomes in cardiovascular interventions involving prosthetic valve frames and nitinol-based implants.

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

Key Features of Superelastic NiTi Alloy Tube for Heart Valve Stents

- Superelasticity and Shape Memory: Recovers from up to 10% strain without permanent deformation, ideal for self-expanding heart valve frames in TAVR procedures.

- High Fatigue Resistance: Withstands millions of cycles under pulsatile loading, ensuring long-term durability in cardiovascular implants.

- Excellent Biocompatibility: Medical grade Nitinol with low nickel release, minimizing inflammation and thrombosis risks in structural heart devices.

- Corrosion Resistance: Superior performance in physiological environments, preventing degradation in blood-contact applications like valve stents.

- Precise Dimensional Control: Custom tubing for laser-cut nitinol frames, offering radial force and flexibility for optimal anchoring in aortic or mitral valve positions.

- Thermal Transformation Properties: Tunable Af temperature for reliable deployment in transcatheter heart valve systems.

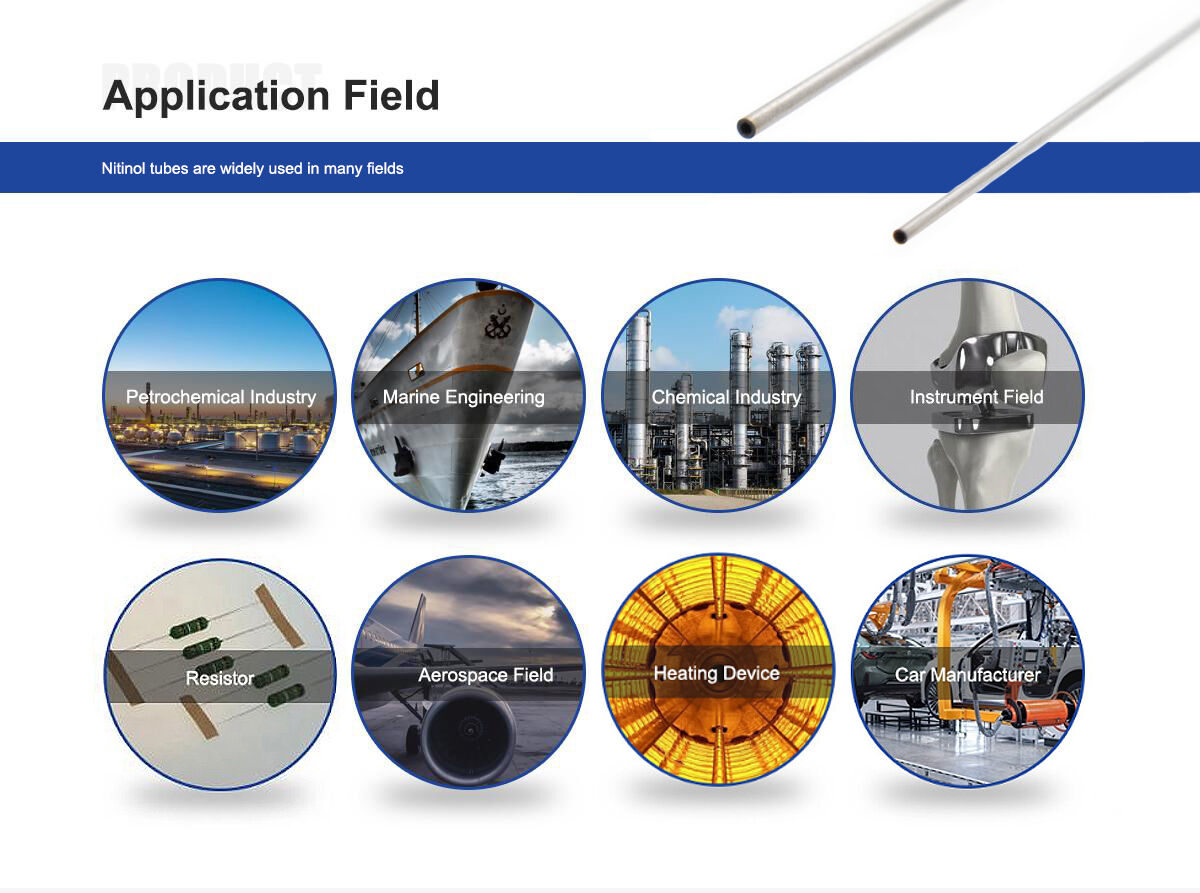

Applications of Medical Grade Nitinol Tubing in Cardiovascular Devices

This DLX NiTi alloy tube is primarily utilized in:

- Transcatheter Heart Valve Frames: Providing structural support for prosthetic aortic, mitral, and pulmonary valves in minimally invasive replacements.

- Self-Expanding Stents for Valve Implantation: Enabling low-profile catheter delivery and precise expansion in cardiovascular interventions.

- Structural Heart Implants: Supporting hybrid tissue-engineered valves and next-generation TAVI/TMVR devices.

- Cardiac Repair Systems: Ideal for nitinol-based frames requiring kink resistance, flexibility, and high cyclic fatigue endurance in beating heart environments.

1.What makes Nitinol ideal for heart valve frames?

Nitinol's superelasticity and shape memory allow frames to compress for catheter delivery and self-expand reliably at body temperature, while offering superior fatigue life for lifelong cardiac cycling.

2.Is this NiTi tubing medical grade and biocompatible?

Yes, our DLX tube meets medical grade standards (e.g., ASTM F2063) with proven biocompatibility, low thrombogenicity, and excellent corrosion resistance for permanent cardiovascular implants.

3.What are the advantages over stainless steel or cobalt-chromium for valve stents?

Nitinol provides greater flexibility, higher recoverable strain, and better fatigue resistance, reducing trauma during deployment and improving long-term performance in dynamic heart valve applications.

4.Can this tubing be customized for specific heart valve designs?

Absolutely – we offer tailored dimensions, Af temperatures, and surface finishes to optimize radial force and deployment characteristics for transcatheter valve frames.