DLX Nichrome Resistance Heating Wire for High Temperature

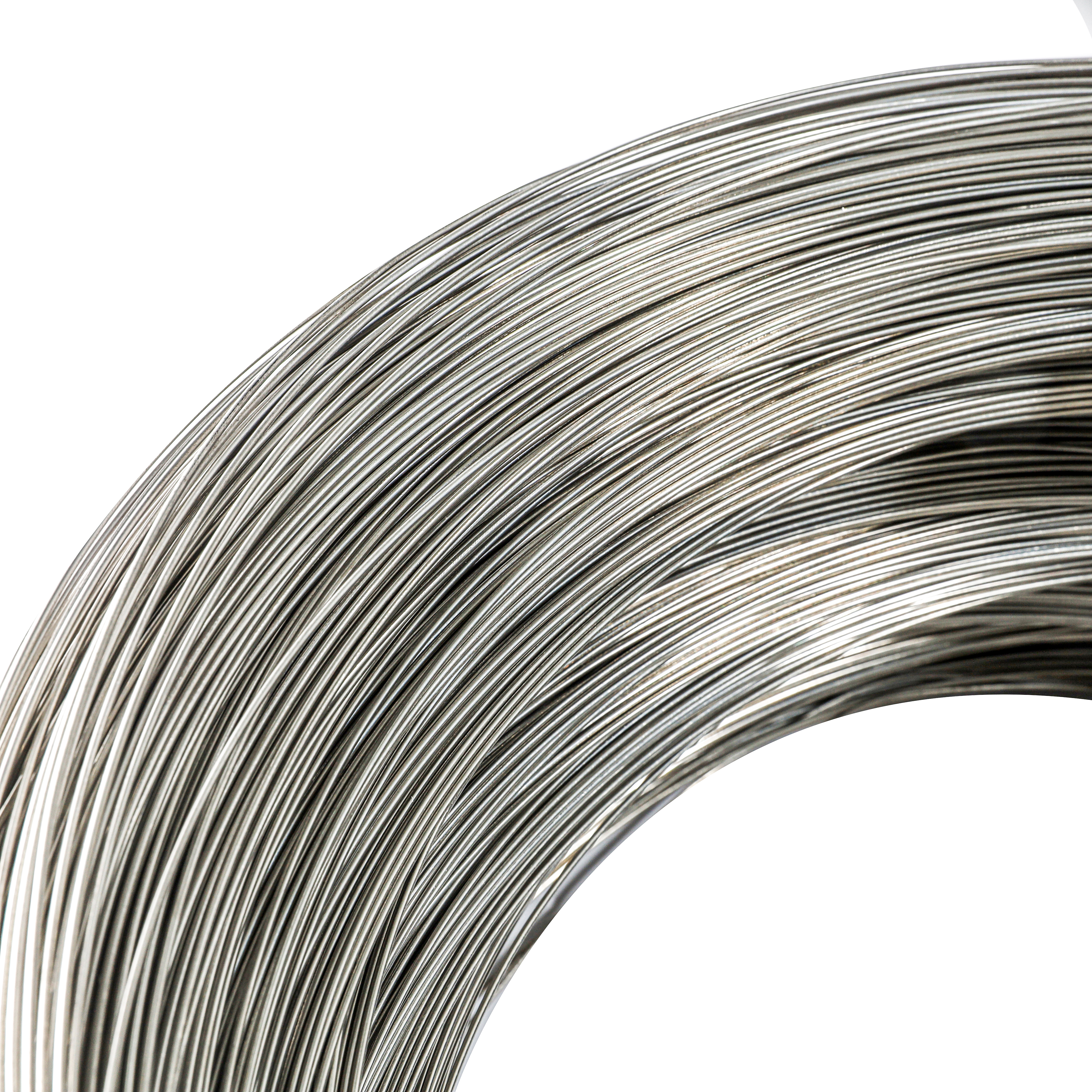

Discover the Reliable DLX Cr20Ni80 Nichrome Wire, engineered specifically for demanding industrial furnaces. This premium nichrome heating wire offers exceptional resistance to oxidation and corrosion, ensuring longevity in high-temperature environments up to 1200°C. Made from a precise Cr20Ni80 alloy composition, it provides stable electrical resistance and uniform heat distribution, making it a top choice for furnace heating elements, kiln wiring, and thermal processing equipment.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Superior Oxidation Resistance: The Cr20Ni80 nichrome alloy composition provides excellent protection against oxidation in high-temperature furnace environments, extending the lifespan of heating elements.

- High Electrical Resistivity: With a stable resistivity of approximately 1.09 μΩ·m, this nichrome resistance wire ensures efficient heat generation for industrial heating coils and thermal processing.

- Excellent Thermal Stability: Capable of withstanding temperatures up to 1200°C, making it ideal for demanding applications in electric furnaces and kiln heating systems.

- Corrosion-Resistant Design: The nickel-chromium blend offers robust resistance to corrosive atmospheres, perfect for harsh industrial settings involving nichrome wire for furnaces.

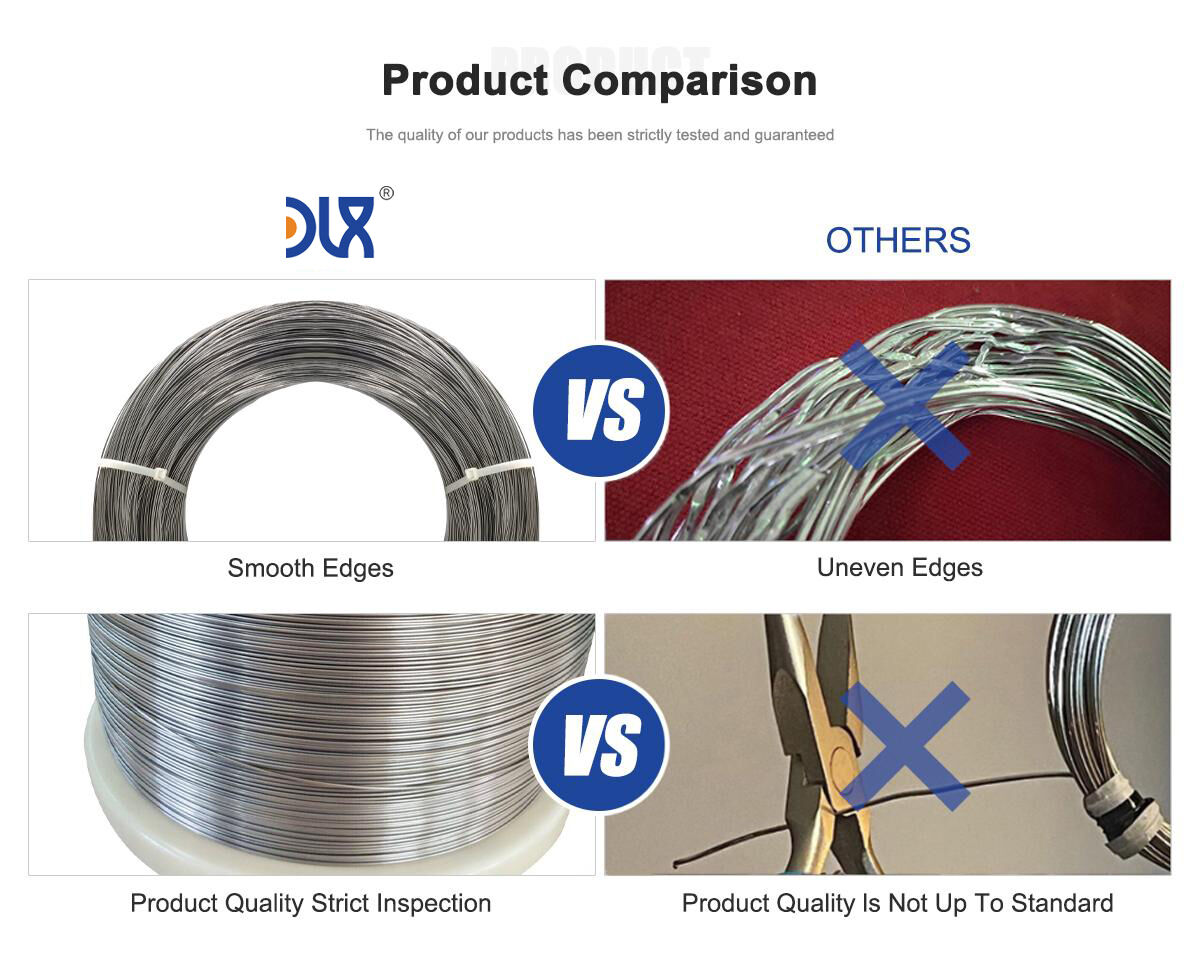

- Flexible and Customizable: Available in various diameters and lengths, this reliable nichrome heating wire can be tailored for specific resistance heating element needs, enhancing versatility in manufacturing.

- Energy-Efficient Performance: Uniform heat distribution minimizes energy waste, supporting cost-effective operations in high-temp wire applications and industrial thermal equipment.

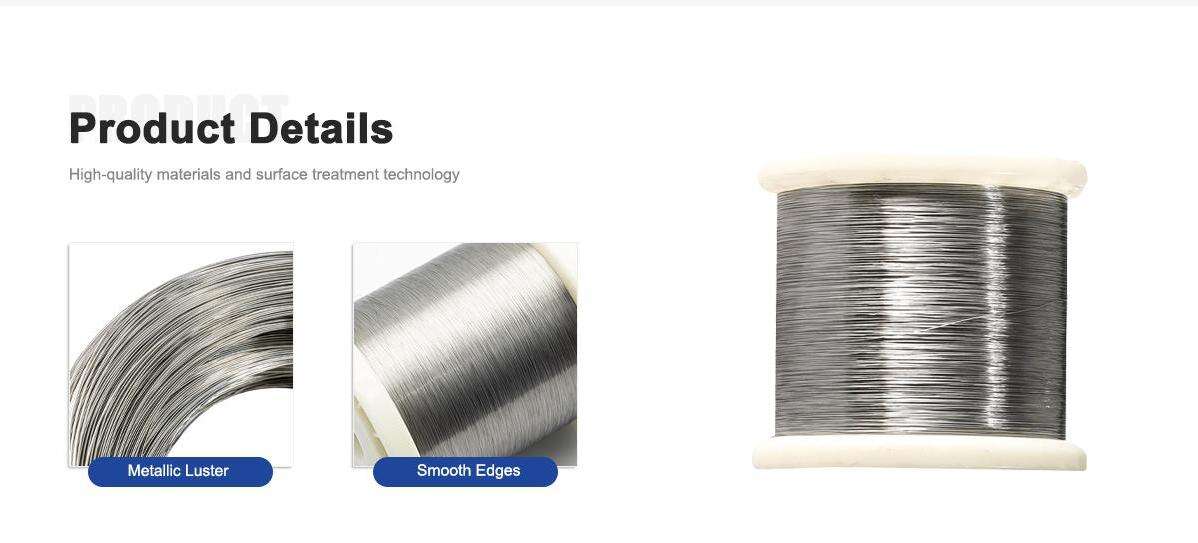

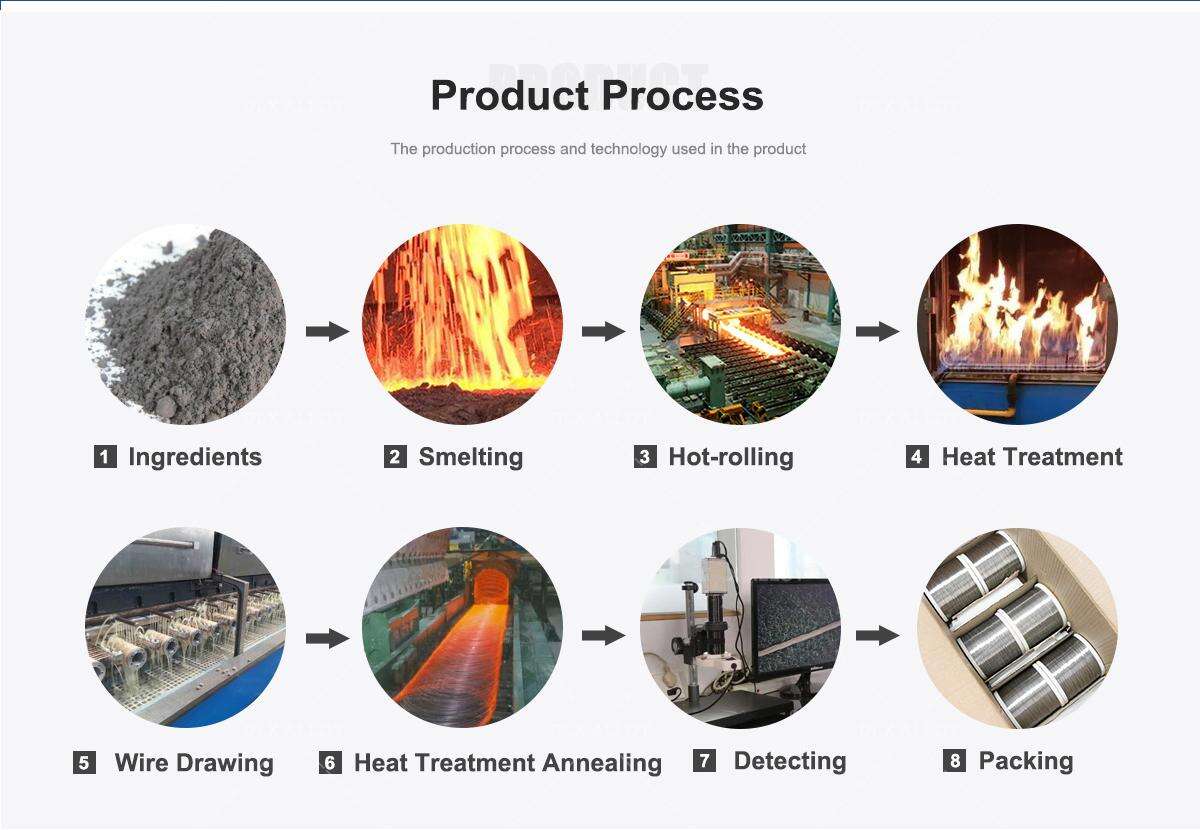

Product Overview: DLX Cr20Ni80 Nichrome Alloy Wire

DLX Cr20Ni80 Nichrome Wire stands out as a high-quality resistance heating wire designed for industrial furnaces and high-heat applications. Composed of 20% chromium and 80% nickel, this nichrome alloy wire excels in environments requiring superior thermal stability and electrical resistivity. As a versatile heating element material, it is widely used in electric furnaces, annealing ovens, and heat treatment systems. Our reliable nichrome wire ensures optimal energy efficiency and durability, supported by rigorous quality testing to meet international standards for industrial heating solutions. Ideal for professionals seeking robust nichrome resistance wire options, it combines affordability with high-performance features for seamless integration into existing furnace setups.

Key Characteristics of Reliable DLX Cr20Ni80 Nichrome Heating Wire

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Uses of DLX Cr20Ni80 Nichrome Alloy Wire:

- Industrial Furnaces and Kilns: Essential for heating elements in electric furnaces, providing reliable performance in metal melting, ceramics firing, and glass annealing processes using nichrome resistance wire.

- Heat Treatment Equipment: Utilized in annealing ovens and quenching systems where high-temperature nichrome wire ensures precise temperature control for metallurgical applications.

- Laboratory and Research Settings: Ideal for custom heating coils in scientific instruments, offering stable resistance heating for experiments involving high-temp alloy wires.

- Manufacturing and Processing Industries: Applied in wire-wound resistors, foam cutting tools, and hot wire cutters, leveraging Cr20Ni80 nichrome for efficient industrial heating solutions.

- Aerospace and Automotive Components: Supports thermal testing and component hardening in high-heat environments, where durable nichrome furnace wire is critical for reliability.

- Custom Heating Solutions: Perfect for DIY or specialized setups requiring flexible nichrome heating elements, such as in 3D printing extruders or custom kiln wiring.

DLX Cr20Ni80 Nichrome Resistance Wire FAQs:

1.What is the maximum operating temperature for DLX Cr20Ni80 Nichrome Wire?

This nichrome heating wire can reliably operate up to 1200°C in industrial furnace applications, depending on the environment and installation method for optimal resistance performance.

2.How does Cr20Ni80 Nichrome Alloy compare to other resistance wires?

Compared to alternatives like Kanthal, Cr20Ni80 nichrome alloy wire offers better oxidation resistance at high temperatures, making it a preferred choice for furnace heating elements and long-term industrial use.

3.Can this nichrome wire be used in corrosive environments?

Yes, the nickel-chromium composition provides excellent corrosion resistance, ideal for harsh industrial settings involving high-temp wire in chemical processing or metalworking furnaces.

4.What diameters are available for DLX Cr20Ni80 Nichrome Resistance Wire?

We offer a range of diameters from 0.1mm to 5mm, customizable for specific heating coil designs in electric furnaces and thermal resistance applications.

5.How to install nichrome wire in an industrial furnace?

Ensure proper coiling and support structures to avoid sagging; consult nichrome wire suppliers for guidelines on voltage, current, and safety in high-temperature heating systems.