DLX Nichrome Resistance Heating Wire for High Temperature

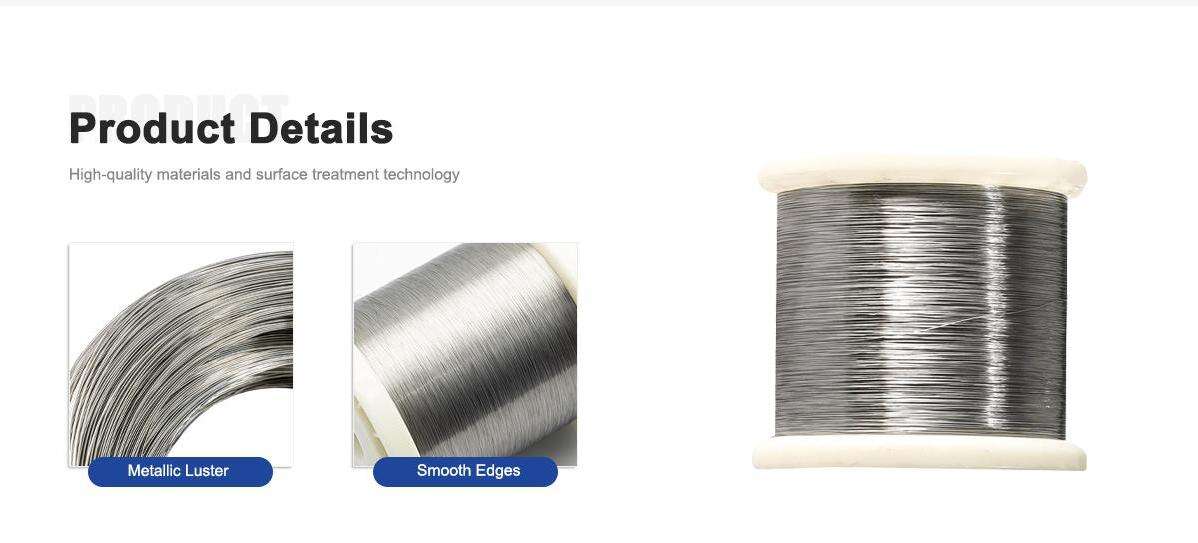

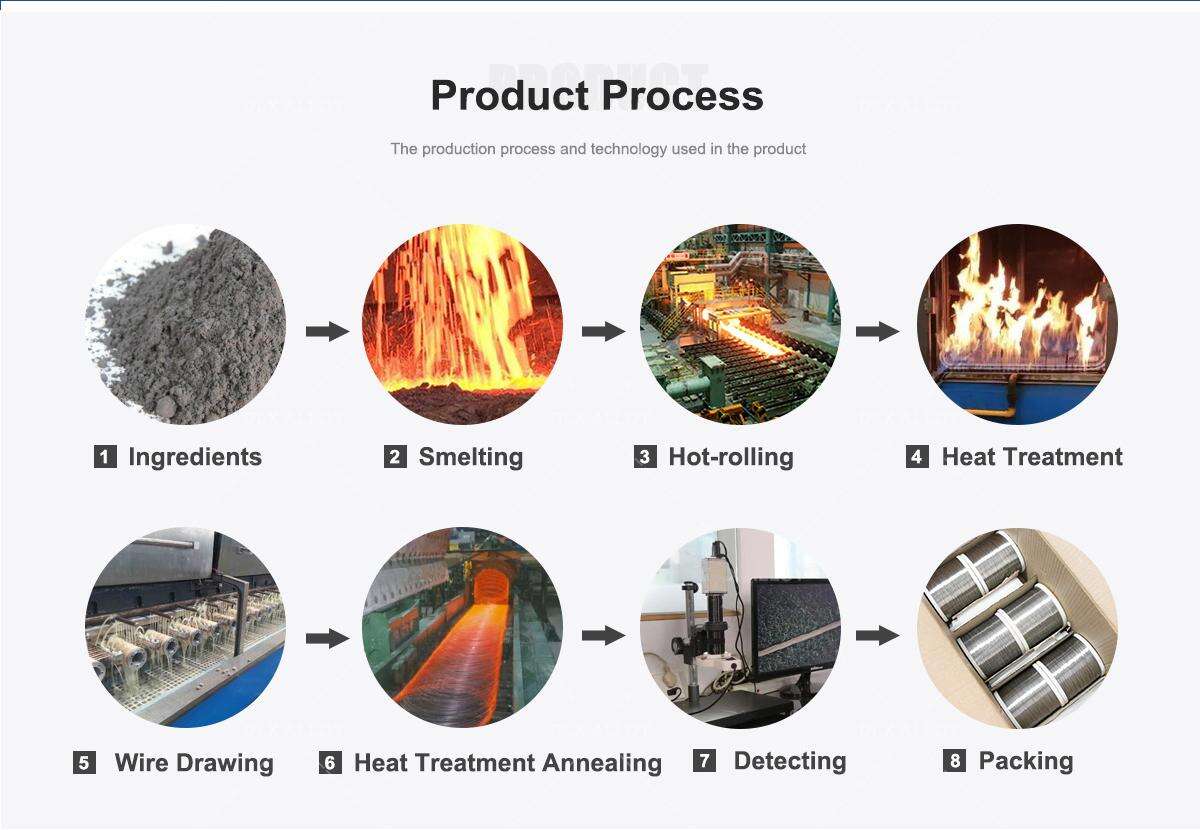

Discover our premium Nichrome resistance heating wire, engineered for exceptional performance in high-temperature environments. This versatile nichrome alloy wire offers superior oxidation resistance and thermal stability, making it perfect for electric heating elements, industrial furnaces, and precision heating applications. Crafted from a nickel-chromium blend, our resistance wire ensures consistent electrical resistivity and longevity, even under extreme conditions up to 1200°C.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Superior Oxidation Resistance in Nichrome Wire: Our nichrome resistance wire withstands high temperatures without oxidizing, extending lifespan in demanding electric heating element applications.

- Consistent Electrical Resistivity for Alloy Heating Wire: Maintains stable resistance across a wide temperature range, ensuring precise control in resistance heating wire setups and furnace wire installations.

- High-Tensile Strength Nichrome Wire for Durability: Built tough for industrial use, this high-temperature wire resists breakage and deformation, perfect for long-term heating coil and thermal wire projects.

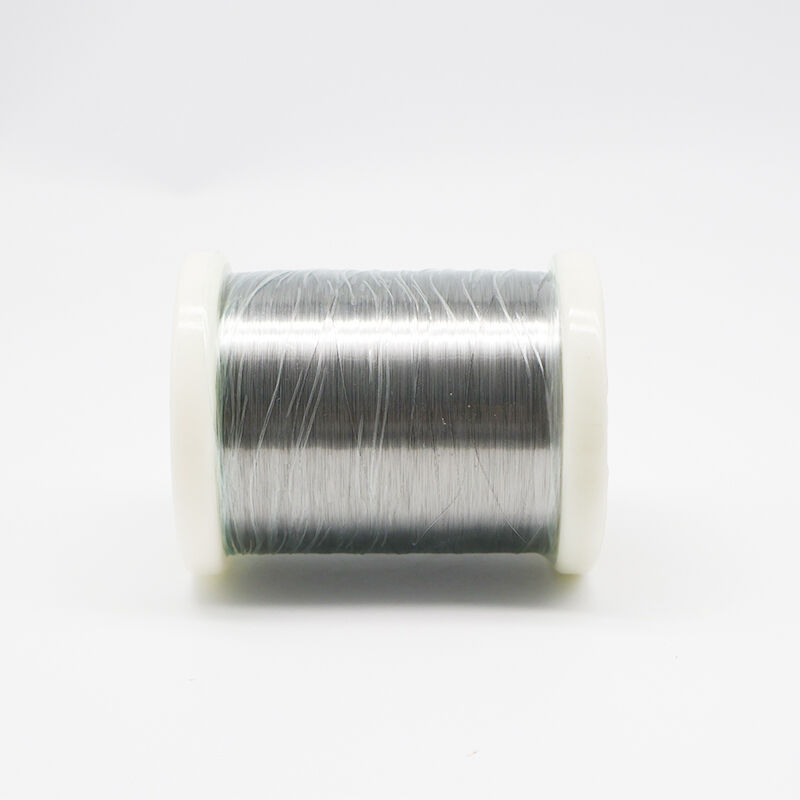

- Versatile Gauge Options in Resistance Wire: Available in multiple diameters, allowing customization for specific electric resistance heating needs, from fine nichrome alloy wire for precision work to thicker strands for heavy-duty applications.

- Corrosion-Resistant Properties of Nichrome Heating Wire: Excels in humid or corrosive environments, making it a reliable choice for alloy wire in laboratory and manufacturing heating solutions.

Nichrome Resistance Heating Wire Overview:

Our Nichrome resistance heating wire is a top-choice material for high-temperature heating needs, combining nickel and chromium for optimal electrical resistance and durability. As a leading nichrome wire supplier, we offer various gauges and lengths to suit diverse applications, from industrial heating coils to custom electric resistance heating setups. This overview highlights how our alloy heating wire excels in maintaining stable resistance values, resisting corrosion, and delivering efficient thermal output. Ideal for users seeking high-quality resistance wire for furnaces, our product supports seamless integration into heating systems worldwide, ensuring safety and efficiency in high-heat operations.

Key Features of Nichrome Alloy Wire

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Nichrome Resistance Wire Applications:

- Industrial Furnace Heating with Nichrome Wire: Ideal for constructing heating elements in kilns and ovens, where high-temperature resistance wire ensures even heat distribution and energy efficiency.

- Electric Appliance Manufacturing Using Resistance Heating Wire: Commonly used in toasters, hair dryers, and space heaters as durable nichrome alloy wire for reliable thermal performance.

- Laboratory and Scientific Equipment with Alloy Heating Wire: Supports precise temperature control in incubators, hot plates, and testing devices, leveraging the stability of electric heating elements.

- DIY and Hobby Projects Involving High-Temperature Wire: Perfect for custom coils in vaping devices or model making, where nichrome resistance heating wire offers safe and effective heat generation.

- Aerospace and Automotive Applications for Furnace Wire: Employed in high-heat testing and component manufacturing, benefiting from the robustness of nichrome wire in extreme conditions.

Nichrome Alloy Wire FAQs:

1.What is Nichrome resistance heating wire made of?

Nichrome wire is an alloy primarily composed of nickel (80%) and chromium (20%), providing excellent electrical resistivity and oxidation resistance for high-temperature applications like electric heating elements and furnace wire.

2.How high can temperatures go with this nichrome alloy wire?

Our high-temperature wire can operate effectively up to 1200°C (2192°F), making it suitable for demanding resistance heating wire tasks in industrial and laboratory settings without losing integrity.

3.Is nichrome resistance wire safe for electric heating element use?

Yes, when used properly, nichrome heating wire is safe due to its non-toxic composition and stable performance. Always follow installation guidelines for alloy wire to prevent overheating in thermal applications.

4.What gauges are available for this resistance heating wire?

We offer a range of gauges from 18 AWG to 32 AWG, allowing flexibility for various nichrome wire projects, from heavy-duty furnace heating to fine electric resistance heating coils.

5.Can nichrome wire be used outdoors in high-temperature environments?

While primarily designed for indoor use, our alloy heating wire's corrosion resistance makes it viable for protected outdoor applications, such as in weather-resistant electric heating systems or industrial setups.