DLX Grade 1 Pure Titanium Wire - High Corrosion Resistant for Medical and Eyewear

Commercially Pure Grade 1 Titanium Wire – Ultra-High Corrosion Resistant, Biocompatible Material for Medical Implants and Hypoallergenic Eyewear Frames

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

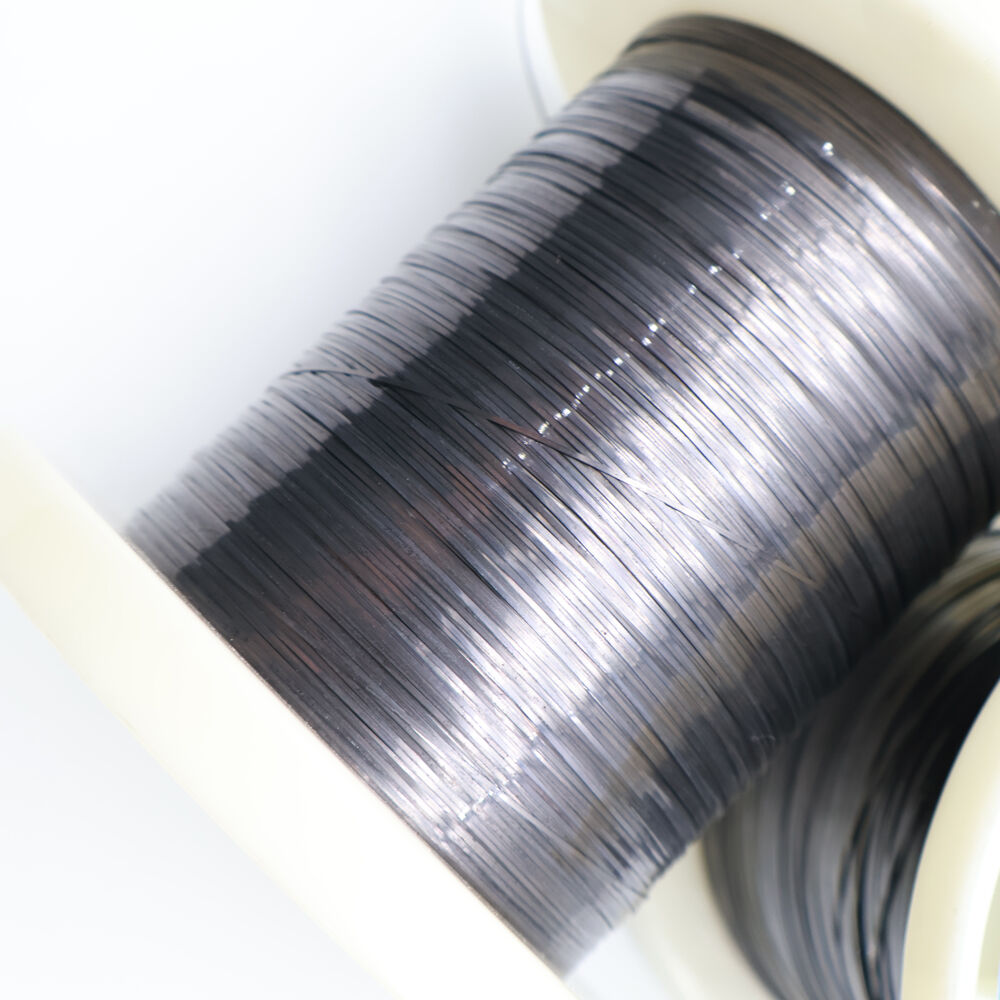

Product Overview:Grade 1 Pure Titanium Wire

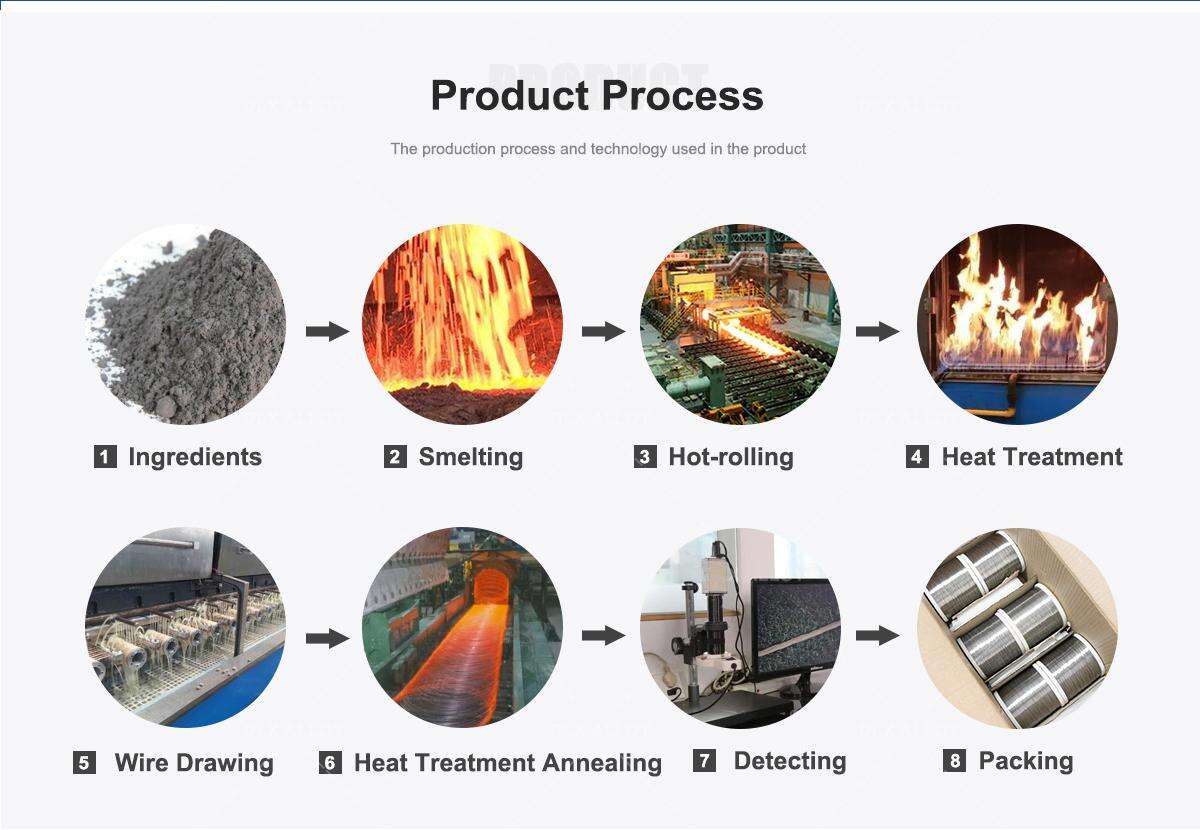

Our DLX Grade 1 pure titanium wire stands out as the softest and most ductile commercially pure titanium variant, featuring excellent corrosion resistance, high biocompatibility, and a superior strength-to-weight ratio. This medical-grade titanium wire forms a protective oxide layer that prevents degradation in harsh environments, including exposure to seawater, chemicals, and humatitaniumn tissue. Widely trusted in medical implants such as sutures, stents, bone fixation, and dental devices, it integrates seamlessly with the body while minimizing irritation. In eyewear applications, this hypoallergenic titanium wire provides lightweight comfort, fatigue resistance, and durability for eyeglass frames and optical components. Choose this versatile high corrosion resistant titanium wire for reliable performance in precision engineering.

| Grade 1 Titanium Wire Chemical Composition | |||||||||

| Grade | N | C | H | Fe | O | AL | V | Pa | Mo |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | ||||

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | ||||

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | ||||

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | ||||

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | ||

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | |||

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 0.2-0.4 | |

Key Features of Grade 1 Titanium Wire

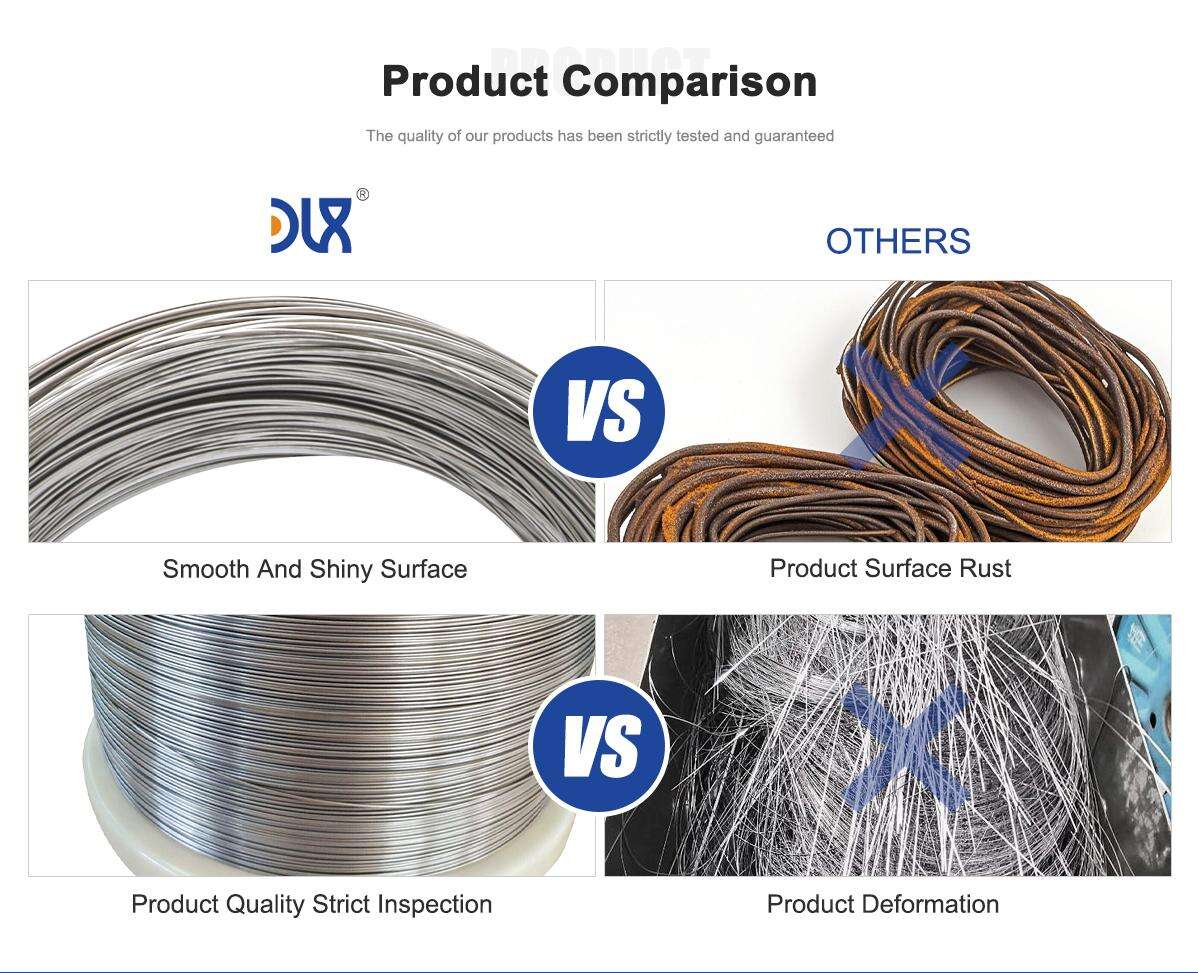

- Exceptional Corrosion Resistance: Naturally forms a stable oxide film, offering superior protection against bodily fluids, chemicals, and marine environments compared to stainless steel.

- Outstanding Biocompatibility and Hypoallergenic Properties: Non-toxic and non-irritating, ideal for medical-grade applications like implants and hypoallergenic eyewear frames to prevent skin reactions.

- High Ductility and Formability: The most pliable pure titanium wire grade, easily shaped for complex orthodontic wires, surgical sutures, or flexible eyeglass components.

- Lightweight with High Strength-to-Weight Ratio: 45% lighter than steel yet incredibly strong, perfect for reducing weight in medical devices and comfortable titanium eyewear.

- Excellent Weldability and Fatigue Resistance: Supports precise fabrication for long-term durability in pacemaker leads, dental implants, and robust optical frames.

Applications of High Corrosion Resistant Pure Titanium Wire

- Medical and Healthcare Uses: Essential for biocompatible implants, including cardiovascular stents, bone screws, orthodontic archwires, surgical instruments, and pacemaker components due to its resistance to bodily corrosion.

- Eyewear and Optical Industry: Preferred for hypoallergenic eyeglass frames, hinges, and temples – lightweight, durable, and comfortable for daily wear without causing allergies.

- Precision Engineering: Suitable for springs, fasteners, and filtration systems requiring high-purity titanium with superior formability.

- Other Industries: Aerospace springs, chemical processing equipment, and marine applications benefiting from extreme corrosion resistance.

Q: What makes Grade 1 titanium wire different from other grades?

A: Grade 1 is the purest commercially pure titanium (99.5%+ Ti), offering the highest ductility, formability, and corrosion resistance – ideal for sensitive medical implants and hypoallergenic eyewear where biocompatibility is critical.

Q: Is this titanium wire safe for medical implants and skin contact?

A: Yes, it's highly biocompatible and hypoallergenic, resisting corrosion from bodily fluids and causing no irritation, making it perfect for surgical devices, dental wires, and eyeglass frames.

Q: Why choose pure titanium wire for eyewear frames?

A: It provides lightweight comfort, exceptional durability, fatigue resistance, and hypoallergenic properties – preventing allergies while maintaining shape for long-term wear.

Q: How does the corrosion resistance benefit applications?

A: The natural oxide layer protects against harsh environments, ensuring longevity in medical devices exposed to fluids and eyewear in daily use.

Q: Can this wire be customized for specific diameters or lengths?

A: Yes, we offer various diameters suitable for medical-grade precision or eyewear manufacturing – contact us for custom options compliant with ASTM standards.