Cr20Ni80 DLX Thermal Spray Wire - High Resistance Nickel Chrome for Heating Elements

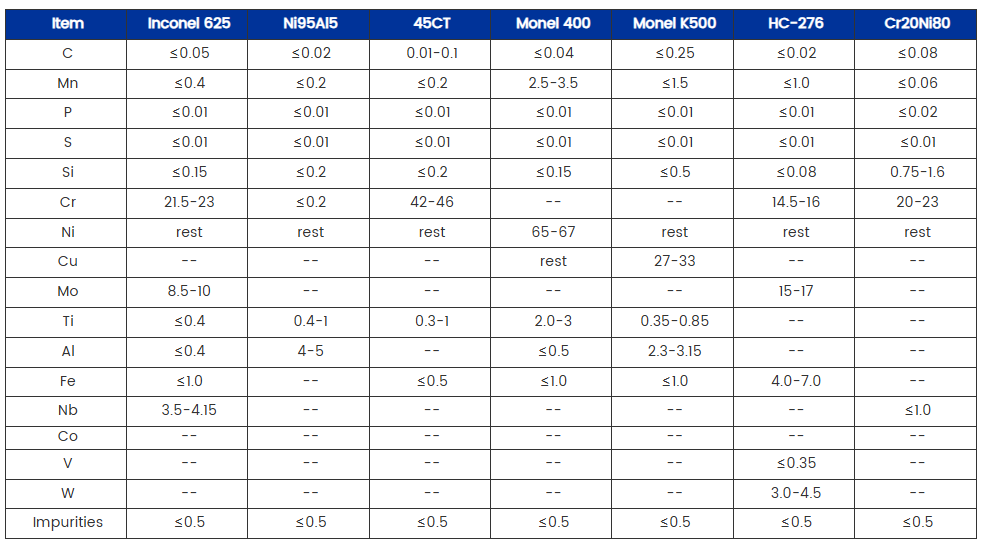

Discover the Cr20Ni80 DLX thermal spray wire, a high-performance nichrome alloy engineered with 20% chromium and 80% nickel for exceptional electrical resistance and durability. This premium nickel chromium wire excels in thermal spraying processes like arc spray and flame spray, producing dense, well-bonded coatings that resist oxidation and corrosion at temperatures up to 1200°C (2200°F).

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Cr20Ni80 DLX Thermal Spray Wire Overview:

The Cr20Ni80 DLX thermal spray wire is a specialized nichrome alloy resistance wire designed for high-resistance applications in heating elements and thermal coatings. Composed primarily of nickel chromium alloy (80% Ni, 20% Cr), it provides outstanding oxidation resistance and corrosion protection, making it suitable for extreme conditions in resistance heating systems. This high-temperature alloy wire is widely used in arc spraying and flame spraying techniques to create robust, low-porosity coatings that enhance component longevity. With excellent electrical resistivity (1.09 ± 0.05 μΩ·m) and form stability, the Cr20Ni80 nichrome wire supports efficient heat generation in electric furnaces, heaters, and automotive parts. Its versatility extends to industries requiring reliable thermal spray solutions, ensuring optimal performance in high-heat resistance wire applications across global markets, including the USA for localized sourcing and compliance.

Cr20Ni80 DLX Thermal Spray Wire Features:

- Superior Oxidation Resistance in Nichrome Wire: Withstands high temperatures up to 1200°C without degrading, ideal for long-term use in heating element wires and thermal spray coatings.

- High Electrical Resistivity for Resistance Heating Applications: Offers consistent resistivity for efficient energy conversion in nickel chromium resistance wires, ensuring stable performance in electric heaters and furnaces.

- Excellent Corrosion and Wear Resistance in Thermal Spray Alloys: Protects against environmental degradation, making it perfect for harsh conditions in arc spray wire and flame spray wire projects.

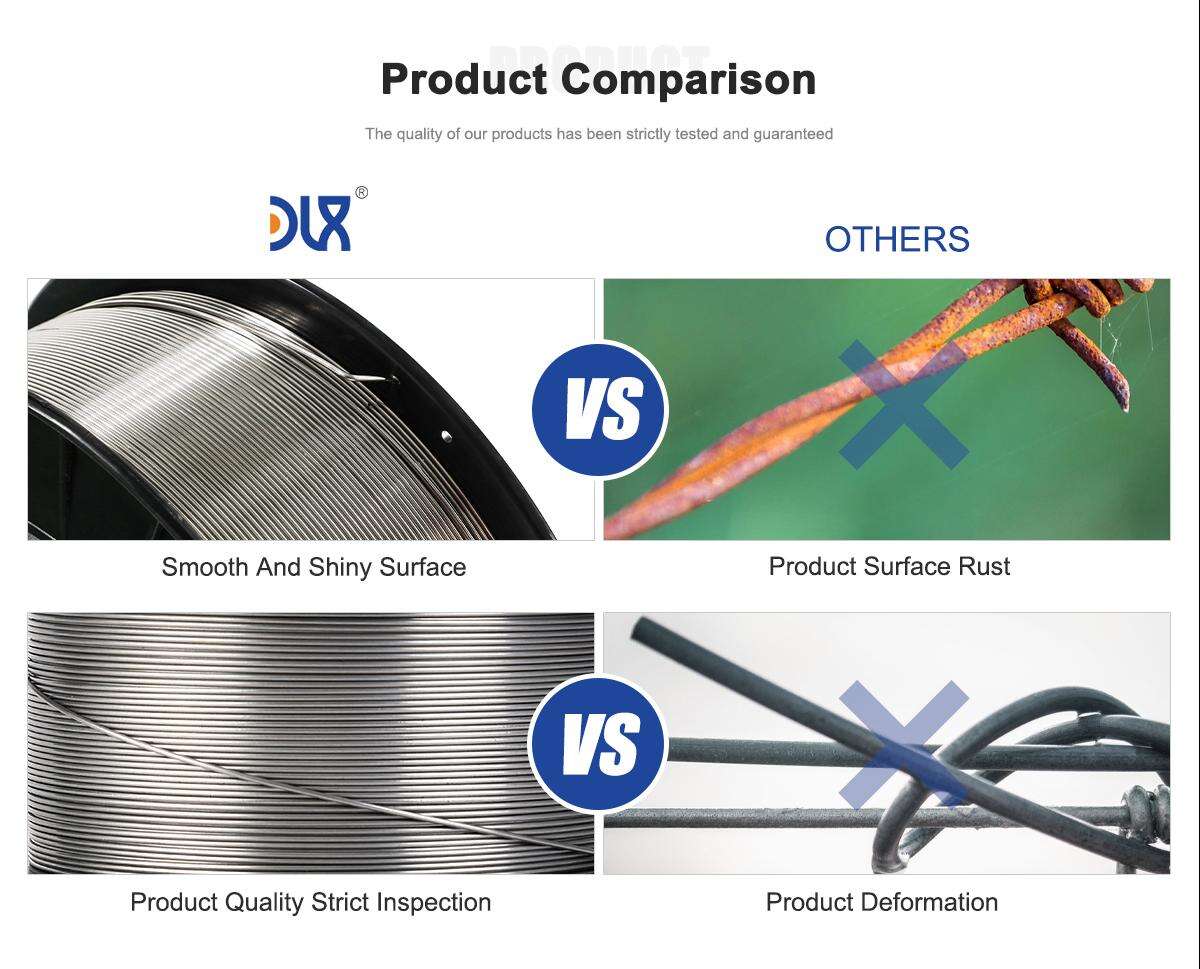

- Dense Bonding and Low Porosity in Nichrome Thermal Coatings: Produces tightly adhered layers during spraying, enhancing durability in high-temperature alloy applications like industrial ovens.

- Good Mechanical Stability and Formability for Heating Wire Fabrication: Features high deformation ability and shockproof qualities, suitable for custom shaping in resistance wire manufacturing.

- Thermal Conductivity and Heat Capacity in Nickel Chrome Sprays: Efficient heat transfer properties support rapid heating in automotive components and aerospace resistance elements.

Cr20Ni80 DLX Thermal Spray Wire Applications:

- Industrial Heating Systems with Resistance Wire: Employed in electric furnaces, ovens, and hot air blowers for reliable nichrome heating elements that maintain consistent temperatures.

- Automotive and Aerospace Components via Thermal Spray Coatings: Used for protective layers on parts requiring oxidation-resistant nickel chromium alloys, enhancing longevity in high-heat environments.

- Electrical Appliances and Heaters with High-Resistance Nichrome Wire: Ideal for toasters, water heaters, and space heaters where Cr20Ni80 wire provides efficient resistance heating.

- Protective Coatings in Manufacturing Using Arc Spray Wire: Applied in flame spraying for corrosion-resistant surfaces on machinery, tools, and infrastructure in demanding industrial settings.

- Resistance Elements in Electronics and Sensors with Nickel Chrome Alloy: Supports precise heat generation in sensors and electronic devices needing stable high-temperature resistance wires.

- Repair and Maintenance in High-Temperature Alloys for Global Industries: Utilized for restoring worn parts in power generation and chemical processing, leveraging nichrome thermal spray for extended service life.

1.What is Cr20Ni80 DLX thermal spray wire made of, and why is it used in nichrome heating elements?

Cr20Ni80 DLX is a nickel chromium alloy wire (80% Ni, 20% Cr) known for its high electrical resistance and oxidation resistance, making it ideal for creating durable heating elements and thermal spray coatings in high-temperature applications.

2.How does the high-resistance nickel chrome wire perform in arc spray and flame spray processes?

This nichrome thermal spray wire produces dense, well-bonded coatings with excellent adhesion and minimal porosity, ensuring superior performance in arc spraying for resistance heating wires and protective layers.

3.What are the temperature limits for Cr20Ni80 nichrome alloy in resistance heating applications?

It operates effectively up to 1200°C (2200°F), providing reliable oxidation and corrosion resistance for long-term use in electric heaters, furnaces, and high-temperature alloy environments.

4.Is this thermal spray wire suitable for corrosion-resistant coatings in industrial settings?

Yes, the nickel chromium resistance wire offers exceptional corrosion and wear resistance, making it perfect for applying protective thermal coatings on machinery and components in harsh industrial conditions.