FeCrAl Resistance Wire 0Cr25Al5 - High Temperature Heating Element Alloy

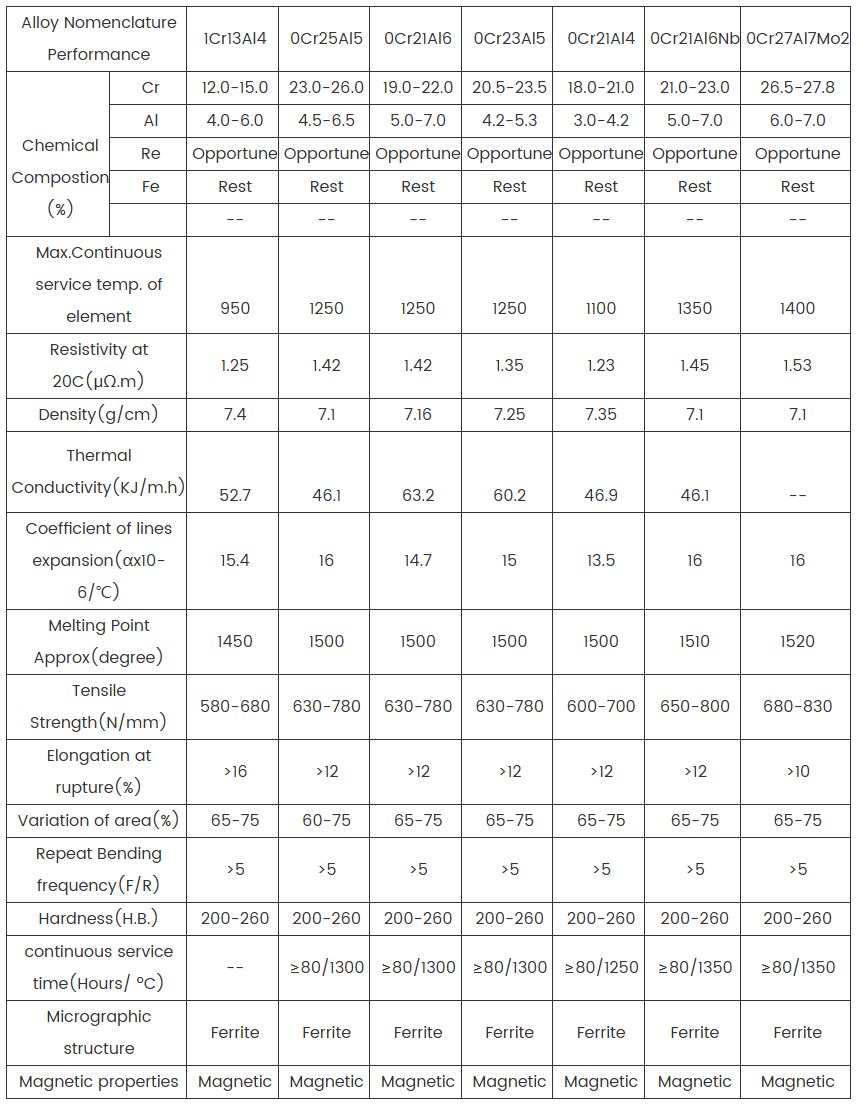

0Cr25Al5 FeCrAl resistance wire is a premium iron-chromium-aluminum (FeCrAl) high temperature heating element alloy. It delivers excellent oxidation resistance, stable resistivity, and superior performance up to 1250°C (2282°F).This electric resistance heating wire is ideal for industrial furnaces, kilns, ovens, and household appliances. Its protective aluminum oxide layer ensures long service life in oxidizing environments.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Ultra-High Operating Temperature — Continuous use up to 1250°C (2282°F) for superior high temp resistance wire performance

- Excellent Oxidation & Corrosion Resistance — Self-forming protective alumina layer ensures long life in oxidizing atmospheres

- High Electrical Resistivity — Stable 1.42-1.50 μΩ·m with low temperature coefficient for consistent heating

- Superior High Temperature Strength — Better creep resistance than Nichrome heating elements

- Cost-Effective Kanthal Alternative — High performance FeCrAl alloy at competitive pricing

- Long Service Life — Up to 2-3x longer lifespan in furnace and oven heating applications

- Easy to Form — Excellent ductility for coils, ribbons, strips, and custom heating elements

✓ Product Description

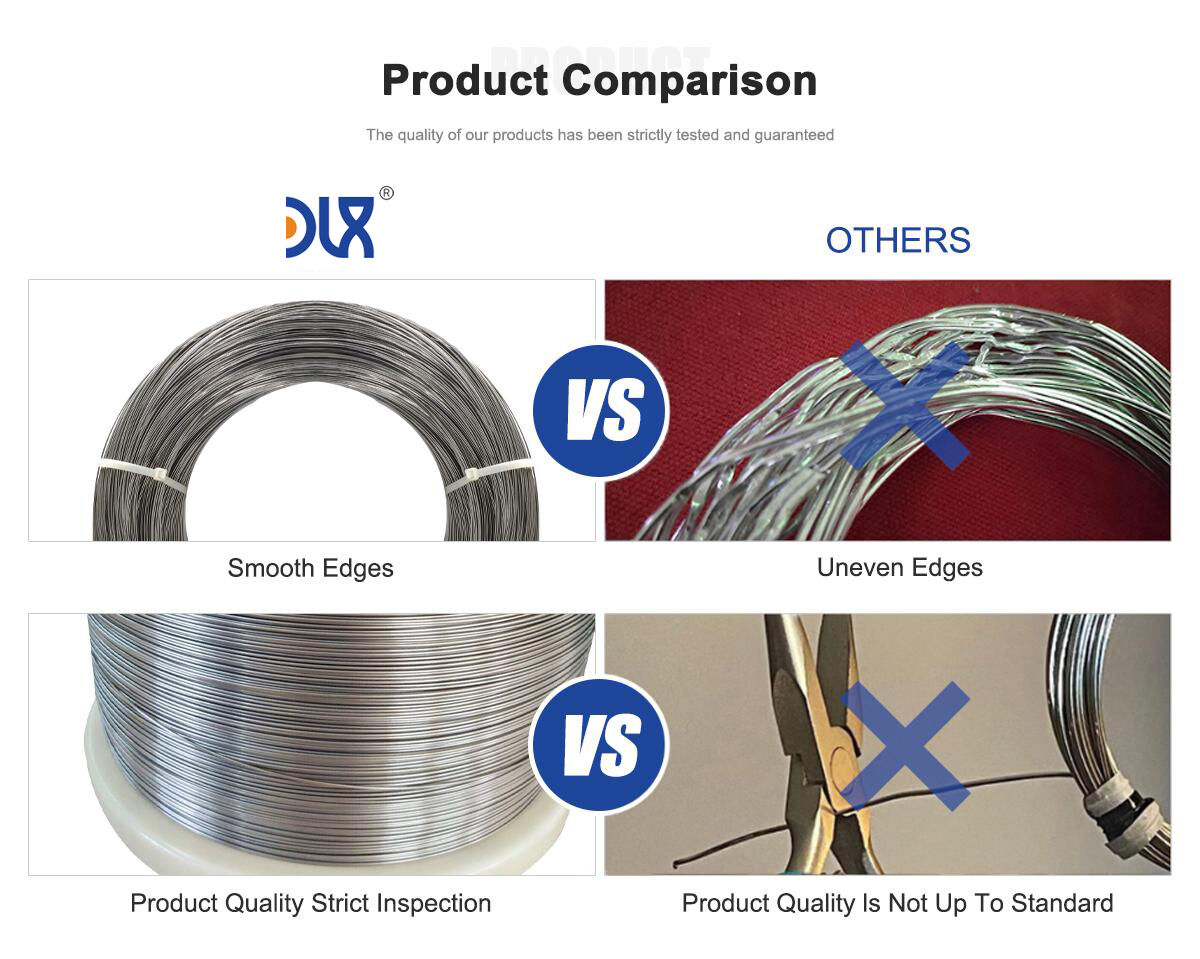

Our FeCrAl 0Cr25Al5 heating element alloy wire offers exceptional high temperature performance, high resistivity (1.42 ~ 1.50 μΩ·m), and outstanding oxidation resistance. Unlike traditional Nichrome, this FeCrAl resistance wire forms a dense, self-protective Al₂O₃ oxide layer that significantly extends service life in high-heat environments.

Key technical advantages include low temperature coefficient of resistance, high hot strength, and excellent formability into coils, ribbons, or strips. It is perfect for electric stove heating elements, ceramic kilns, laboratory furnaces, and industrial heating systems requiring reliable high temperature operation.

✓ Product Features

Key Features & Advantages of 0Cr25Al5 FeCrAl High Temperature Heating Wire

✓ Product Applications

Industrial & Commercial Applications of FeCrAl 0Cr25Al5 Heating Element Alloy

0Cr25Al5 FeCrAl resistance wire is widely used in demanding high temperature environments:

- Industrial electric furnaces, muffle furnaces & heat treatment ovens

- Ceramic kilns, glass melting, and laboratory heating equipment

- Household appliances → electric stoves, ovens, toasters, hair dryers & space heaters

- Automotive exhaust gas heaters and catalytic converters

- Metallurgy, machinery, and high-temperature test equipment

✓ Product FAQ - FeCrAl 0Cr25Al5 High Temperature Resistance Wire

Q: What is the maximum operating temperature of 0Cr25Al5 FeCrAl wire? A: The recommended continuous operating temperature is up to 1250°C (2282°F) in oxidizing atmospheres.

Q: Is 0Cr25Al5 a good replacement for Kanthal or Nichrome heating elements? A: Yes. 0Cr25Al5 is an excellent and more affordable alternative to Kanthal D/A-1, offering better oxidation resistance than Nichrome in high-temperature applications.

Q: What are the main advantages of FeCrAl heating wire over Nichrome? A: FeCrAl resistance wire provides higher maximum temperature, superior oxidation resistance, and longer service life, although it is slightly more brittle after prolonged high-heat use.

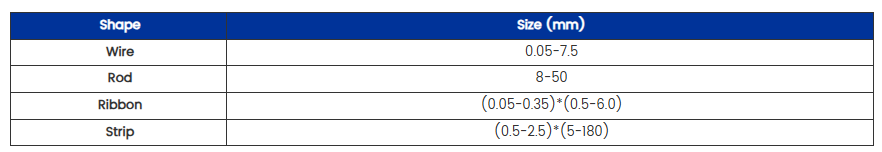

Q: What diameters are available for this resistance heating wire? A: Standard diameters range from 0.02mm to 7.5mm (fine wire to thick heating coil wire).

Q: Can this FeCrAl alloy be used in reducing atmospheres? A: It performs best in oxidizing or neutral atmospheres. For reducing environments, specialized coatings or different alloys may be recommended.