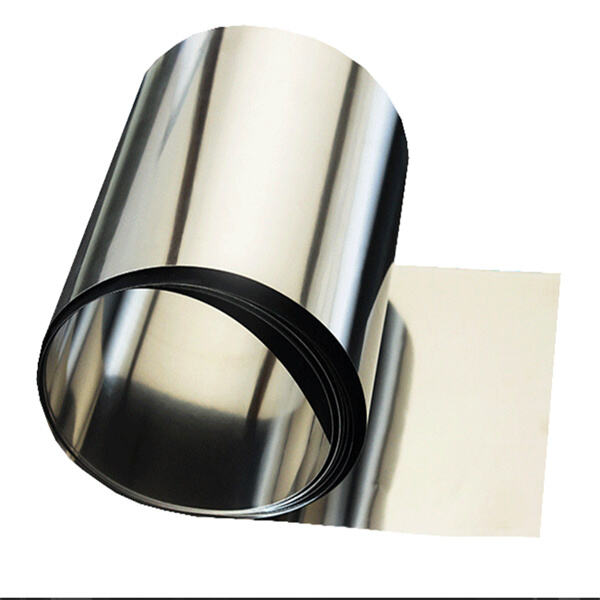

Inconel strip is a special type of super-strong material for many important usages. It is known as Inconel strip, a material designed to withstand high-stress situations for extended periods. Inconel strip is super flexible so, it can be used in various ways for many jobs as well. Let’s find out about Inconel strip and its significance.

Inconel strip is tough, flexible, and used in all sorts of hard jobs. Inconel strip is the strongest material out there, it has a high-performance ratio and can take on even the most challenging tasks that will not compromise any other material. Inconel 718 is therefore ideal for components found in aircraft and rockets where strength and toughness are critical.

Is Inconel stripe ideal for extreme places? Well, inconel material does a very good job at stopping rust, which is what happens when things corrode due to water or chemicals. It is also resistant to such high temperatures that it will not melt or collapse at a temperature of 1250F (675C) which makes it ideal from outer space to the depths of the ocean.

How the Inconel strip resists rust and high temperatures? Inconel strip is consisting of niche metals such as nickel and chromium, which prevent the formation of grains and help it to remain stable even in tough conditions. These metals all do their part to form a protective barrier on the Outside surface of the inconel tube from something that could be damaging to the Inconel strip from water or high temperature.

Inconel Strip One of the most widely used metal alloys: Applications in aero plane and factories are endless. Such general diffusion at highspeed, with temperature change is used as airplane and spaceships strip (Inconel strip). Inconel plate is useful for factories and power plants because it is also resistant to rusts and high temperatures, which means it helps to make it a reliable choice for many tough tasks.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.