Advanced DLX Nichrome Alloy Cr15Ni60 - High Resistivity for Medical

Advanced DLX Nichrome Alloy Cr15Ni60 offers exceptionally high electrical resistivity, superior oxidation resistance, and excellent high-temperature stability. This medical-grade nickel-chromium resistance wire is specifically engineered for demanding medical and healthcare heating applications requiring precision, reliability, and biocompatibility.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Ultra-High Electrical Resistivity (1.11–1.15 μΩ·m) – Ideal for compact, high-efficiency medical heaters

- Exceptional High-Temperature Stability – Continuous service up to 1150°C

- Superior Oxidation & Corrosion Resistance – Perfect for humidified medical environments and sterilization cycles

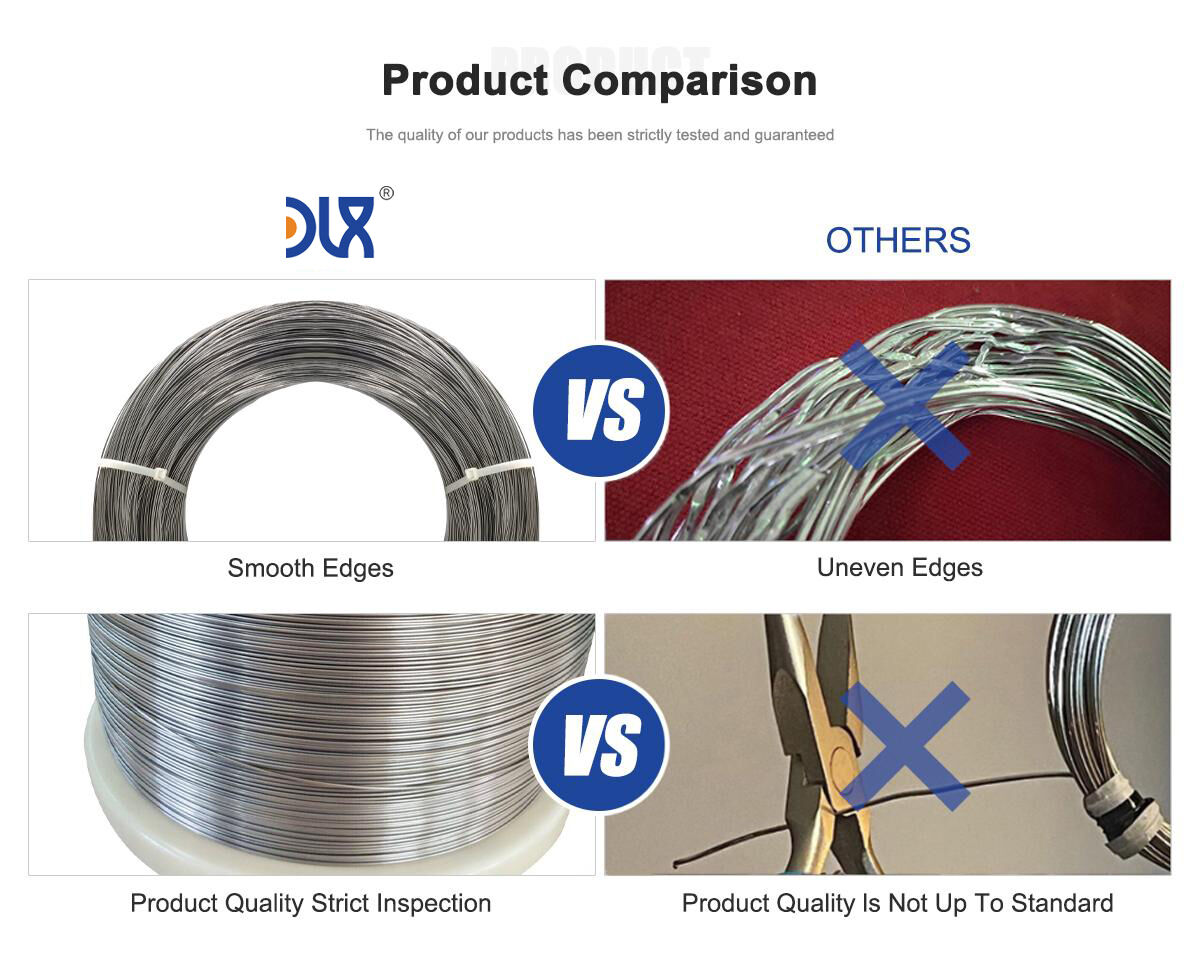

- Medical-Grade Purity & Consistency – Low impurity content, tight dimensional tolerances

- Excellent Mechanical Strength & Ductility – Easy forming into round wire, flat ribbon, or strip

- Long Service Life & Low Drift – Minimal resistance change over time

- Good Weldability & Solderability – Compatible with medical device assembly processes

- RoHS & REACH Compliant – Suitable for global medical device markets

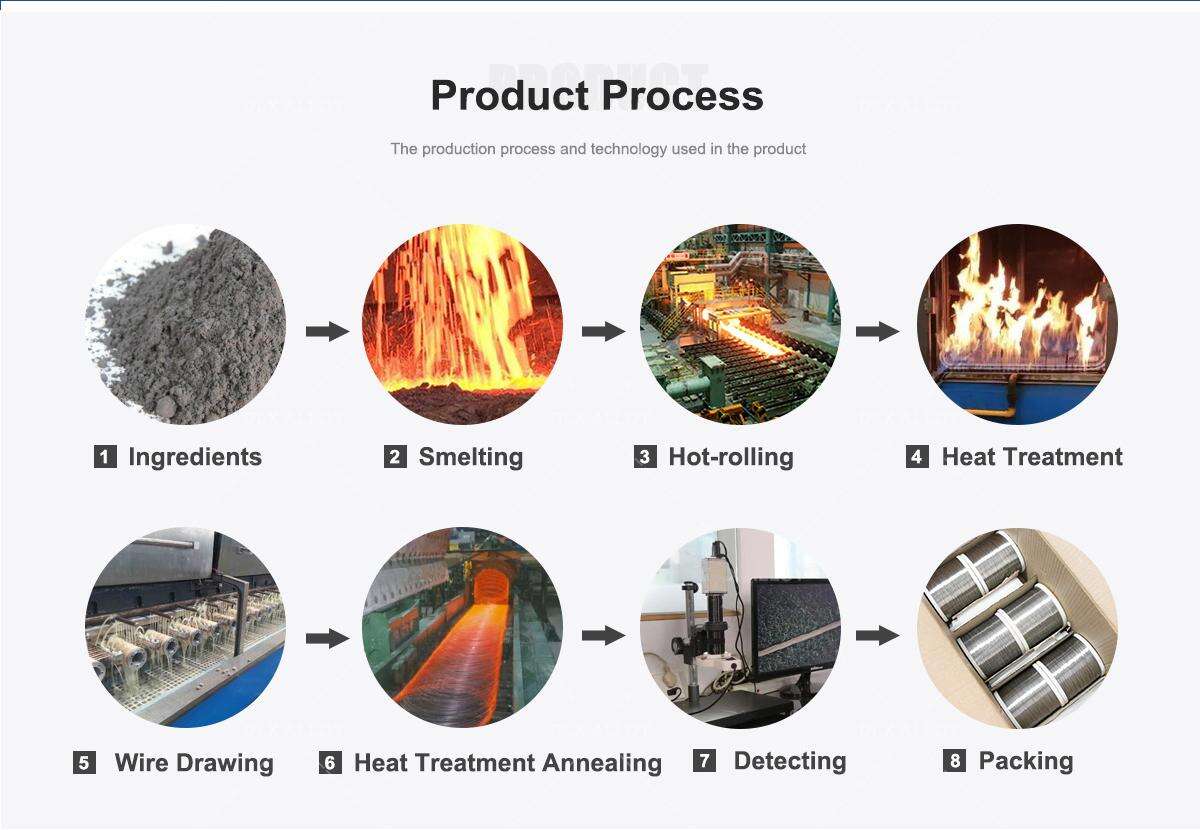

Overview of Advanced DLX Cr15Ni60 Nichrome Alloy

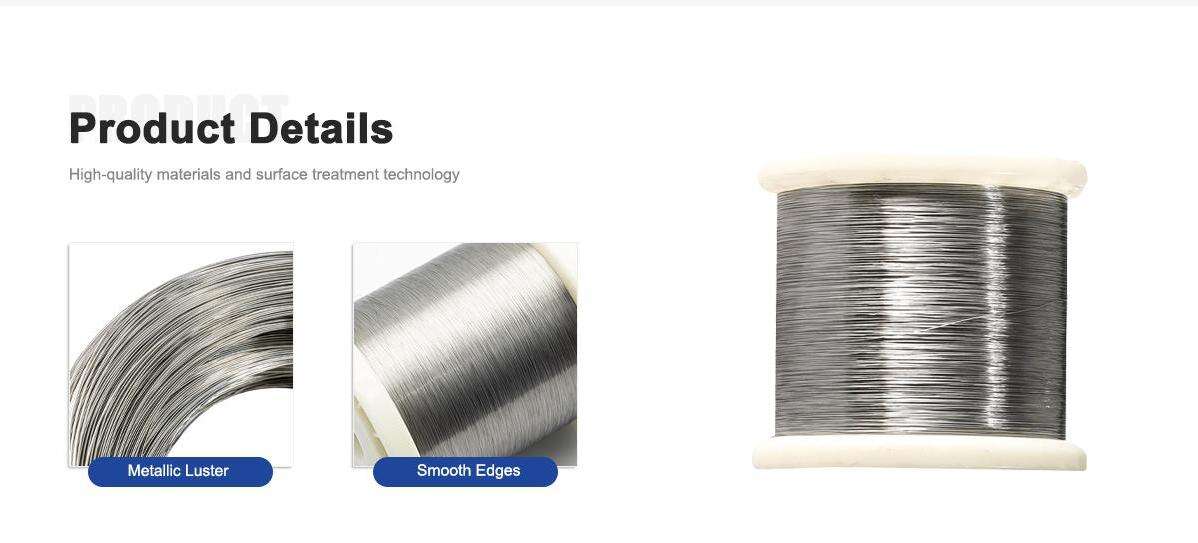

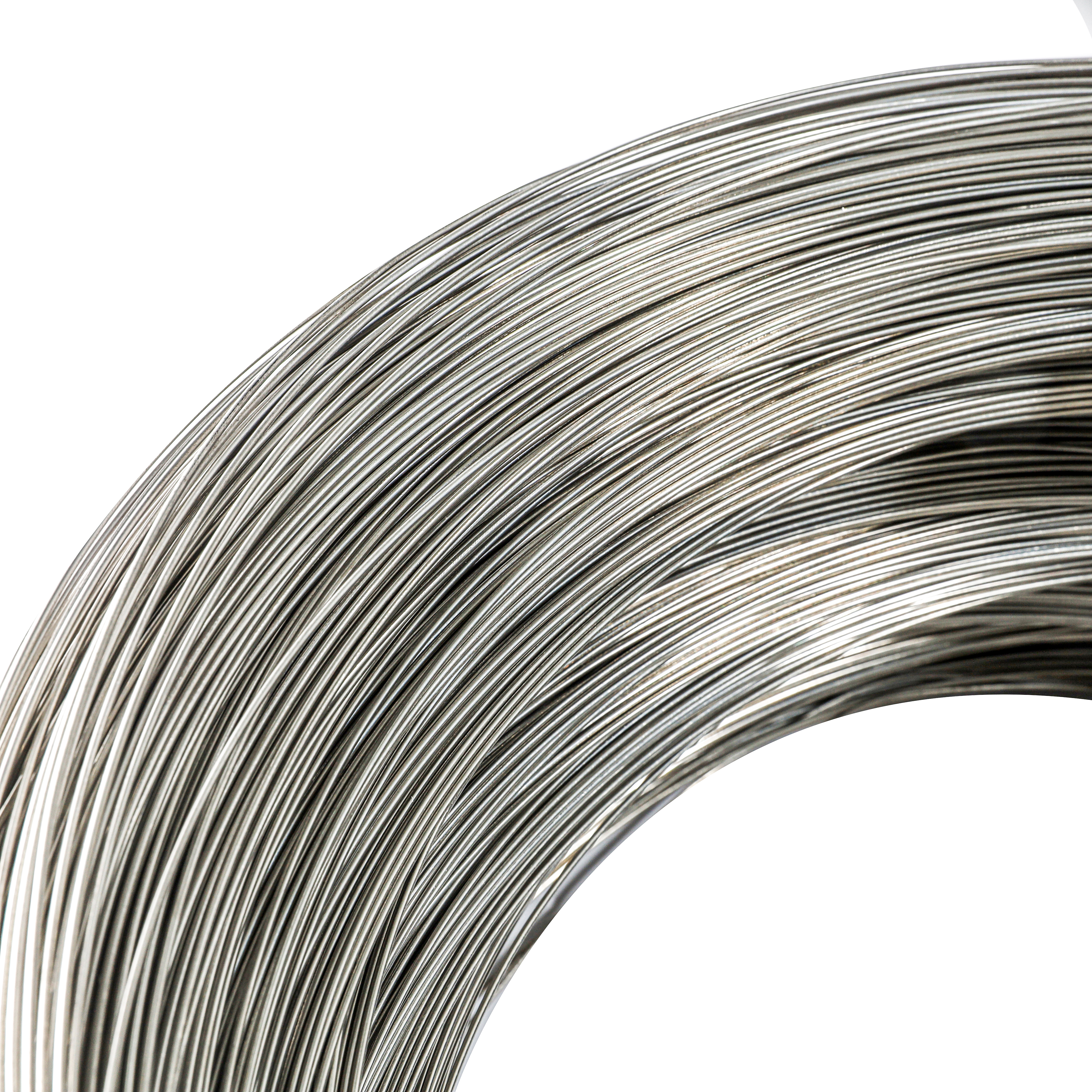

The Advanced DLX Nichrome Cr15Ni60 is a premium nickel-chromium alloy (60% Ni, 15% Cr) developed for high-precision heating applications in the medical and healthcare industries. With outstanding electrical resistivity (1.11–1.15 μΩ·m), this medical-grade nichrome resistance wire delivers consistent performance at temperatures up to 1150°C while maintaining excellent oxidation and corrosion resistance in humid or sterile environments.

Key Features of High Resistivity Cr15Ni60 Nichrome Alloy

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Medical Applications of Cr15Ni60 Nichrome Resistance Wire and Heating Elements

- Respiratory Humidification Systems & Heated Breathing Circuits

- Medical Vaporizers and Nebulizer Heating Elements

- Surgical and Dental Tool Heaters

- Patient Warming Blankets & Blood/Fluid Warmers

- Laboratory Incubators and Diagnostic Equipment Heaters

- Sterilization and Autoclave Heating Components

- Wearable Medical Therapy Devices

- In-Vitro Diagnostic (IVD) and Analytical Instrument Heaters

DLX Cr15Ni60 Nichrome Alloy FAQs:

Q1: What is the resistivity of Cr15Ni60 nichrome alloy?

A: Cr15Ni60 has a high resistivity of 1.11–1.15 μΩ·m at 20°C, making it ideal for compact medical heating elements.

Q2: Is this nichrome wire medical-grade and biocompatible?

A: Yes. Our Advanced DLX Cr15Ni60 is medical-grade with controlled impurity levels and is suitable for respiratory, surgical, and patient-contact heating applications.

Q3: What is the maximum continuous operating temperature?

A: Up to 1150°C in oxidizing atmospheres, with excellent long-term stability.

Q4: Do you offer Cr15Ni60 in round wire, flat ribbon, or strip form?

A: Yes. We supply medical-grade nichrome Cr15Ni60 in round wire (Ø 0.025 mm – 8.0 mm), flat ribbon, and strip forms with tight tolerances.

Q5: Is Cr15Ni60 better than Cr20Ni80 for medical applications?

A: Cr15Ni60 provides higher resistivity and better cost-performance for many medical heating systems, while still offering excellent oxidation resistance and longer service life in humid conditions.

Q6: What certifications and compliance does this nichrome alloy have?

A: RoHS, REACH, ISO 9001, and material certificates with full chemical composition and mechanical properties are available.