99.9% Precision Engineered N4 Nickel Strip High Conductivity

Our 99.9% Precision Engineered N4 Nickel Strip offers exceptional high conductivity, making it an ideal choice for demanding applications in battery connectors, electronic components, and welding tabs. This pure nickel foil strip is crafted from premium N4 grade nickel, ensuring 99.9% purity levels that minimize resistance and enhance electrical performance.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- Superior Purity Levels in N4 Nickel Strip: Achieves 99.9% pure nickel composition, reducing impurities for enhanced conductivity and corrosion resistance in battery welding and electroplating applications.

- High Conductivity Nickel Foil Characteristics: Optimized for low electrical resistance, making it ideal for efficient energy transfer in nickel battery tabs and electronic circuits.

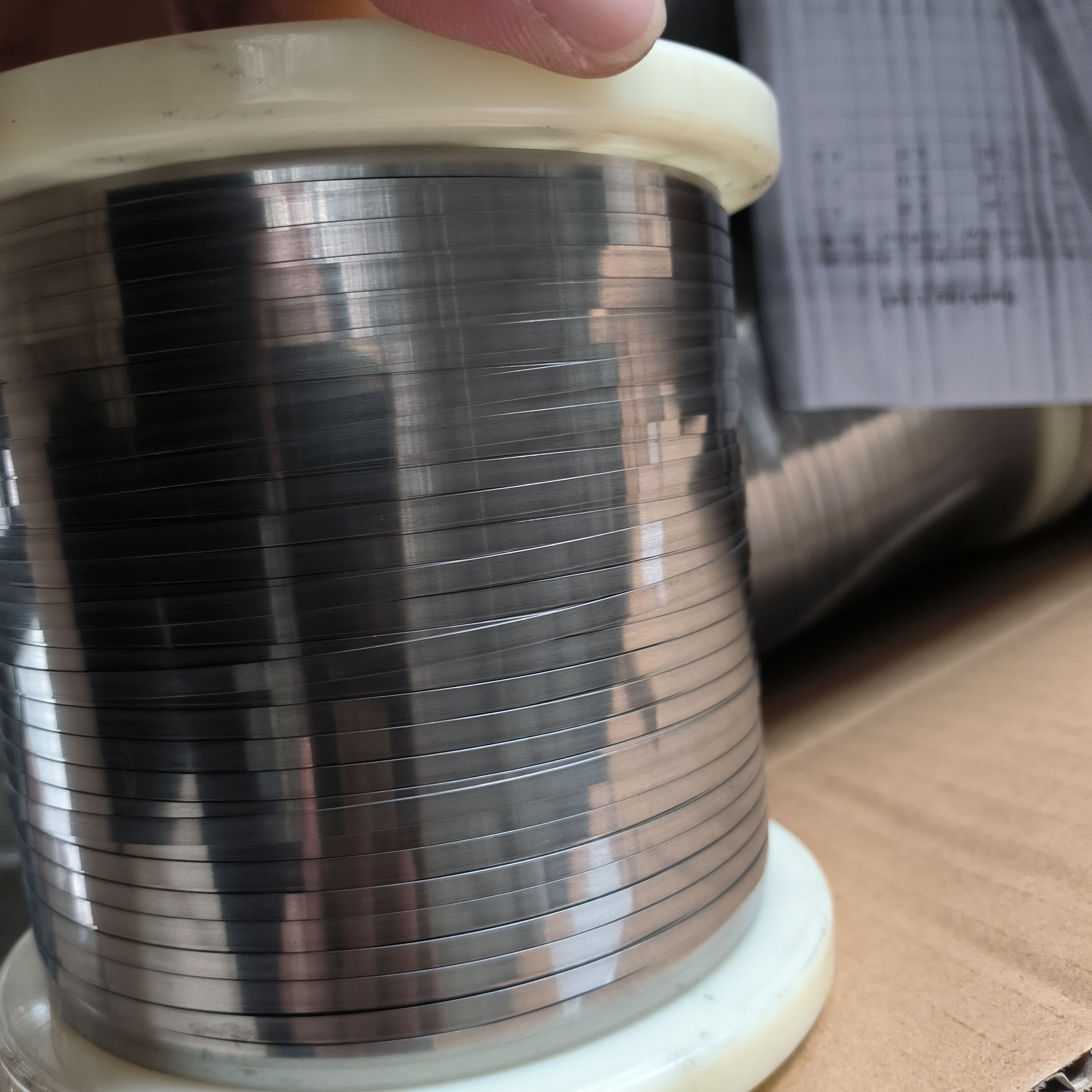

- Precision Engineered Nickel Strip Dimensions: Customizable widths (from 2mm to 200mm) and thicknesses (0.05mm to 0.5mm) for precise fitting in industrial battery manufacturing and welding processes.

- Durable Conductive Nickel Tape Durability: Excellent tensile strength and flexibility, ensuring longevity in high-temperature environments like spot welding and battery assembly lines.

- Eco-Friendly High Purity Nickel Material: Compliant with international standards, including RoHS, for sustainable use in global markets such as European electronics and North American battery production.

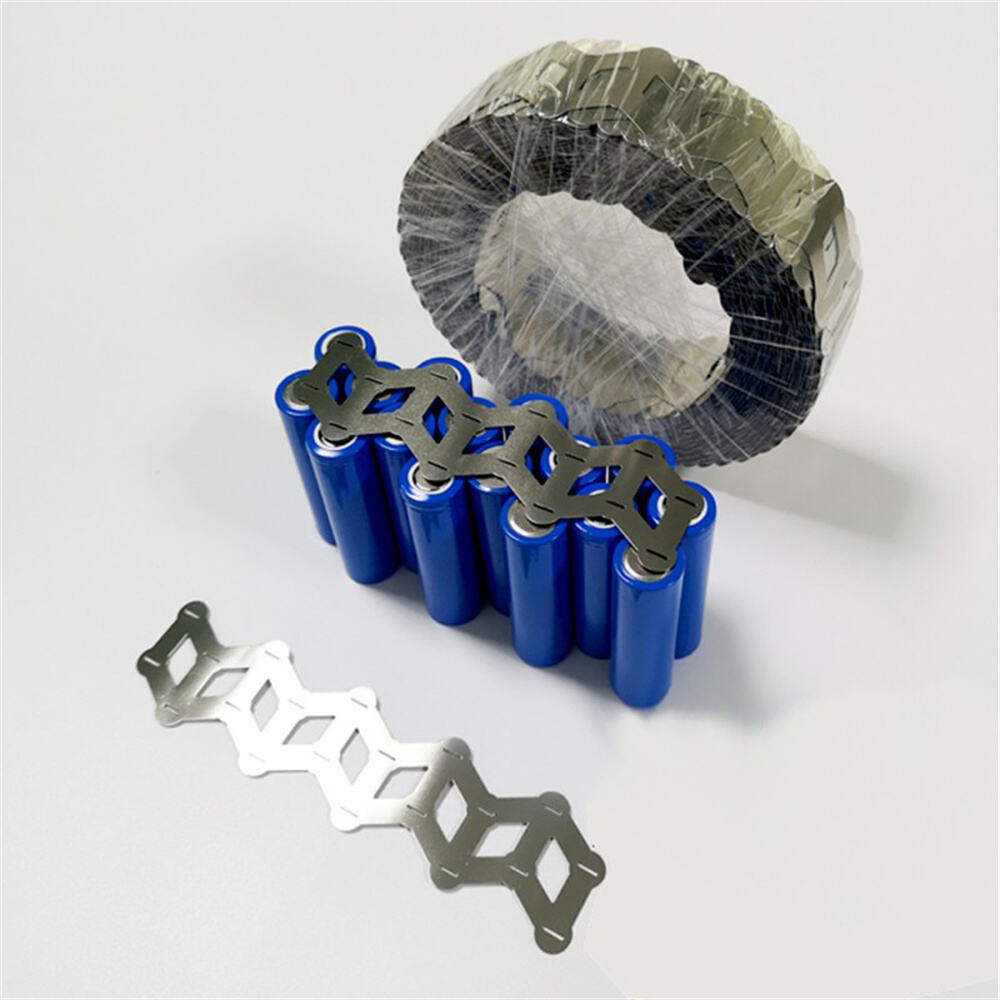

- Versatile Battery Nickel Strip Compatibility: Easily weldable with common techniques, supporting seamless integration into lithium-ion, NiMH, and other battery connector strip designs.

N4 Nickel Strip Overview: Precision Engineering and High Conductivity Benefits

In this N4 nickel strip overview, discover how our 99.9% precision engineered product stands out in the realm of high purity nickel materials for battery and electronics sectors. As a leading conductive nickel strip option, it provides superior electrical conductivity, thermal stability, and mechanical strength, making it essential for modern applications like lithium-ion battery tabs and circuit board connectors. This high purity N4 nickel foil is manufactured using advanced precision engineering techniques to achieve uniform thickness and surface finish, ensuring optimal performance in high-demand environments. With a focus on sustainability, our nickel strip is produced with eco-friendly processes, appealing to industries in regions like Europe where environmental standards are stringent. Explore the versatility of this battery nickel strip, from small-scale prototyping to large-scale industrial use, and understand why it's a top choice for professionals seeking reliable, high conductivity nickel solutions.

Key N4 Nickel Strip Product Features: High Purity, Conductive Design, and Precision Engineering

| Specification | Details |

|---|---|

| Material | N4 N201 Pure Nickel (≥99.9%) |

| Thickness | 0.1mm – 0.3mm (Customizable) |

| Width | Up to 300mm (Customizable) |

| Standard Compliance | ASTM B162, GB/T 2054-2005 |

| Melting Point | 1453°C (2647°F) |

| Tensile Strength | ≥380 MPa |

| Electrical Resistivity | ≤0.099 Ω·mm²/m |

Applications of 99.9% Pure Nickel Strip in Electronics

- Battery Manufacturing with Ni201 Nickel Tape: Essential for lithium-ion battery tabs and connectors, providing corrosion resistance and reliable conductivity in energy storage solutions worldwide.

- Electronic Components Using Pure Nickel Foil: Ideal for shielding, grounding, and circuit elements in devices like smartphones, laptops, and automotive electronics, enhancing durability in humid or corrosive settings.

- Industrial Sensors and Instrumentation Nickel Strip: Applied in sensors exposed to chemical environments, ensuring stable performance in manufacturing plants across Europe and North America.

- Aerospace and Marine Electronics with Corrosion Resistant Tape: Used in high-reliability systems where resistance to saltwater and extreme conditions is critical, supporting global aerospace and marine industries.

- Renewable Energy Applications for N4 Nickel Foil: Integrated into solar panels and wind turbine components for efficient electrical connections in eco-friendly energy systems.

FAQs of N4 Nickel Strip :

1.What is the purity level of this precision engineered N4 nickel strip for high conductivity uses?

Our N4 nickel strip boasts 99.9% purity, ensuring minimal impurities for optimal performance in battery connectors and electronics welding across international standards.

2.How does the high conductivity of this pure nickel foil benefit battery manufacturing applications?

The superior conductivity reduces energy loss, making it ideal for nickel battery tabs in lithium-ion and NiMH batteries, improving efficiency in global EV and renewable energy sectors.

3.Can this conductive nickel tape be customized for specific electroplating and welding needs?

Yes, we offer customizable dimensions and finishes for the N4 nickel strip, suitable for precision engineering in industries like European automotive and North American electronics.

4.Is the high purity N4 nickel material resistant to corrosion in industrial applications?

Absolutely, its 99.9% purity provides excellent corrosion resistance, making it reliable for long-term use in battery assembly, circuit boards, and harsh environmental conditions.